The OEM fuel system of the MK7 becomes a limiting factor as you increase the power level of the cars. Choosing the best solution for your needs is important and the MK7 GTI and R are fortunate enough to have lots of solutions available. So let’s go over how the OEM system works, when you will need to upgrade, and how to choose the best solution for your application.

Please keep in mind that throughout this article the power numbers are in reference to our Mustang Dyno. Power output on different dynamometers may vary. Here’s a video of how a Golf R performs on our Mustang.

To start let’s look into how the OEM MK7 fuel system works. First of all it must be understood that the car injects fuel that is proportional to the amount of air entering the engine in order to achieve a correct air-fuel ratio. The more power you make, the more air enters the motor.

To start let’s look into how the OEM MK7 fuel system works. First of all it must be understood that the car injects fuel that is proportional to the amount of air entering the engine in order to achieve a correct air-fuel ratio. The more power you make, the more air enters the motor.

In order to know how much fuel to inject, the ECU needs to know how much air is being consumed by the motor. The more power you make, the more fuel the engine will be consuming to achieve that power output.

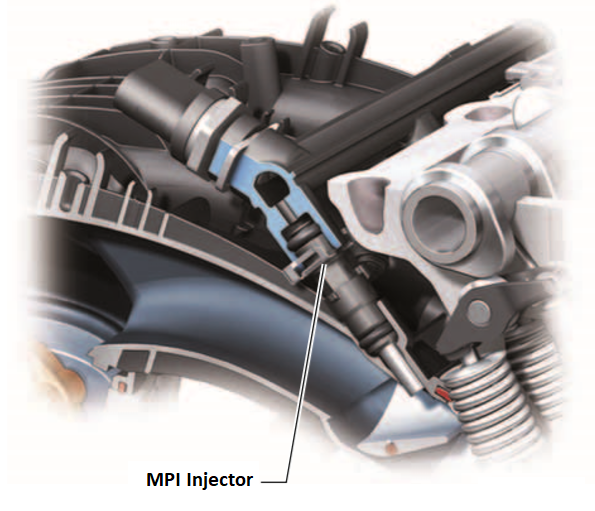

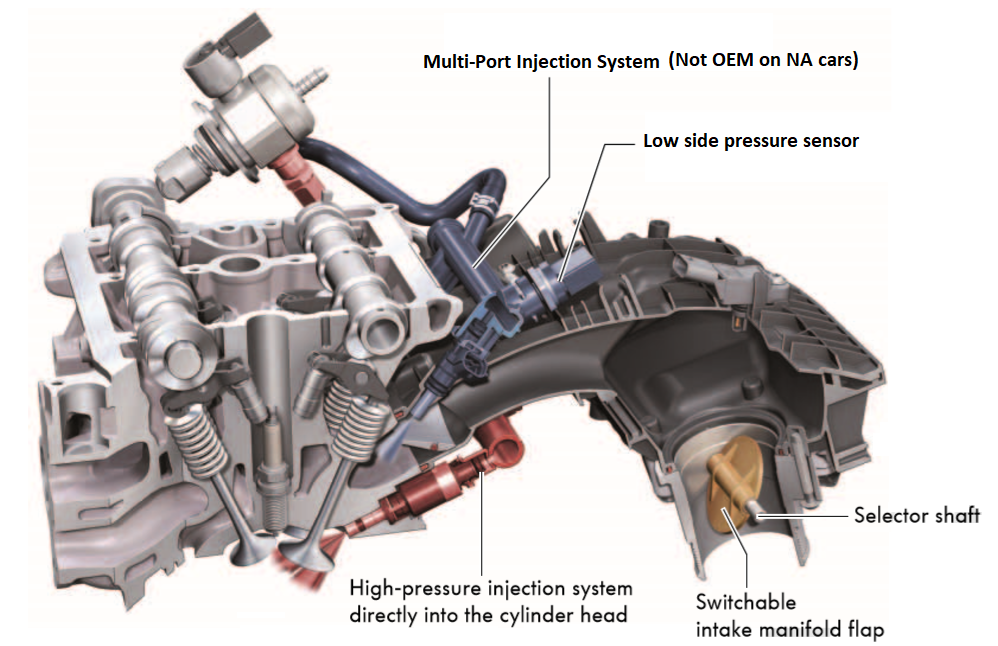

Below is an image showing the MK7 with both the port and direct injection systems in place. In Europe the MK7 GTI/R has both port (blue) and direct injection (red) while in North America the car only came with direct injection. Port injection can be added to North American cars – but more on that later.

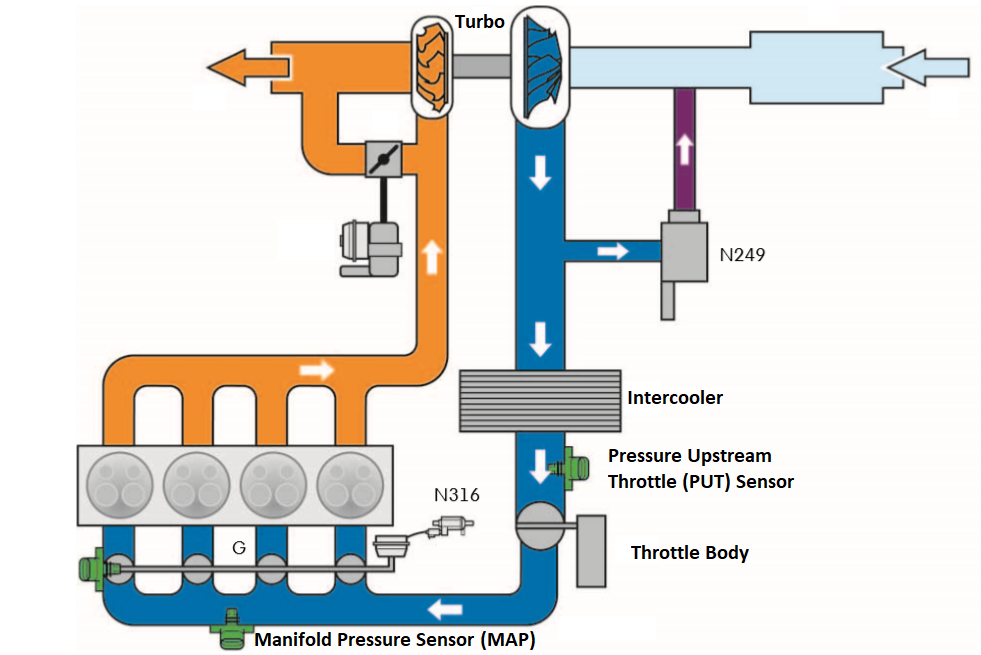

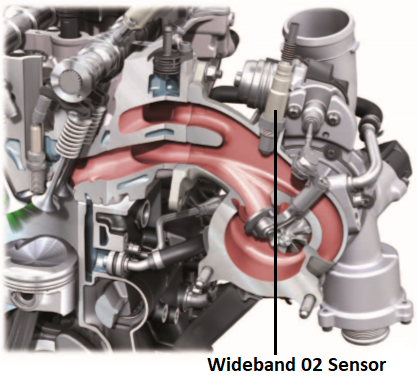

To measure air entering the motor, the MK7 GTI/R use a speed density (pressure) style control system that does NOT contain a MAF sensor. Some of you may be familiar with these and the main difference is that when you use a MAF, you measure airflow directly while when you use pressure, you need to translate that pressure reading into aiflow.

To measure air entering the motor, the MK7 GTI/R use a speed density (pressure) style control system that does NOT contain a MAF sensor. Some of you may be familiar with these and the main difference is that when you use a MAF, you measure airflow directly while when you use pressure, you need to translate that pressure reading into aiflow.

In order to do this the ECU primarily relies on 2 intake pressure sensors, one pre-throttle (PUT) and one post throttle in the manifold (MAP). Along with compensations for air temperature and barometric pressure these pressure readings then go into a volumetric efficiency model to determine how much fuel is required to meet the target Air/Fuel ratio (AFR).

Further to this, the car has an OEM wideband O2 feecback sensor and the ECU constantly adjusts the fueling (under part throttle as well as wide open) to reach the desired AFR. All in all, this is a fast and modern ECU and it controls fueling very well under all conditions.

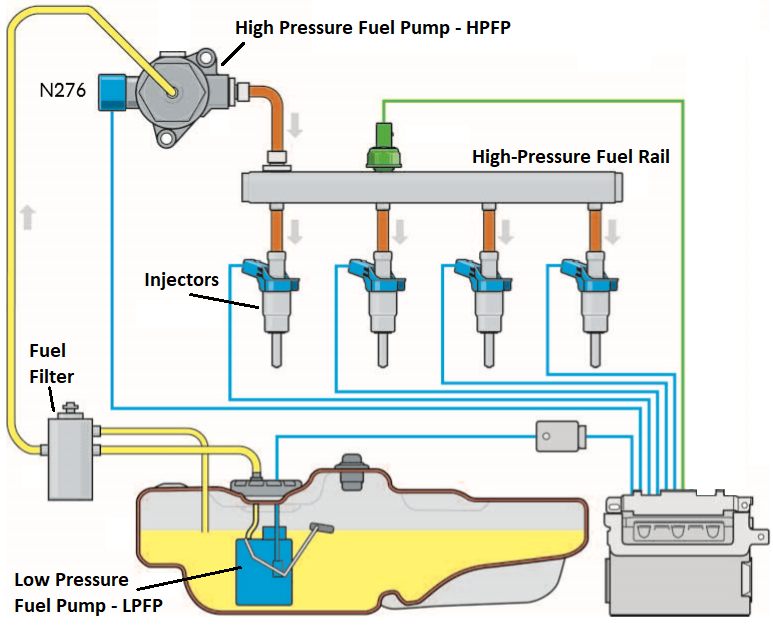

On the delivery side on North American GTIs and Rs, we have 3 main components: Low pressure fuel pump (LPFP) (in the tank), high pressure pump driven by the exhaust camshaft (HPFP) and the high pressure DI injectors spraying right inside the combustion chamber. Under high load/boost the MK7 injects fuel with a pressure of around 2900psi.

On the delivery side on North American GTIs and Rs, we have 3 main components: Low pressure fuel pump (LPFP) (in the tank), high pressure pump driven by the exhaust camshaft (HPFP) and the high pressure DI injectors spraying right inside the combustion chamber. Under high load/boost the MK7 injects fuel with a pressure of around 2900psi.

OEM Fuel System Limitations

As we talk about fuel system limitations keep a few things in mind:

1. Pump gas without ethanol or other alcohol added to the fuel gives you the most headroom in terms of how much mass the fuel system can deliver. However the engine will experience knock the earliest using this type of fuel limiting the power by reaching the knock limit. Running E30 fuel requires around 10% more fuel volume to be injected and running full E85 requires around 30% more fuel volume to be injected compared to ethanol free gas. As you raise the knock limit using ethanol blended fuels allowing you to add knock-free power, you run out of fuel system headroom. You can run a little leaner without knock on ethanol blended fuels that can recover some the fueling headroom – however on a Golf R with the IS38 or an upgraded turbo you will often run out of headroom on the stock system.

2. Ambient temperatures have a big effect on turbocharger efficiency and fuel requirements. A car will require significantly more fuel running the same boost in freezing weather than it will in the heat of summer. If we want a reliable setup, consider the requirements during both winter and summer and build your system for the peak demand you will experience.

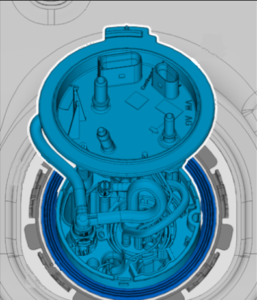

OEM LPFP: Starting with the first component in the fuel delivery line we have the Low Pressure Fuel Pump (LPFP) – This in-tank transfer pump is controlled electronically by the OEM ECU via the tune. The OEM LPFP on the MK7 can provide fuel for up to around 400 WHP for the GTI and R.

OEM HPFP: The line from the LPFP feeds into the inlet of the HPFP (High Pressure Fuel Pump). The HPFP is driven by the exhaust camshaft of the engine and pressure is controlled via a solenoid. A four-point cam lobe on the camshaft drives the HPFP. As the engine RPM increases, the HPFP’s ability to pump a greater volume of fuel per unit of time also increases. Because of this we see the HPFP start to suffer at peak torque. You can tell the OEM HPFP is struggling if you see pressure drops under high boost and this usually happens around 380-400 WTQ.

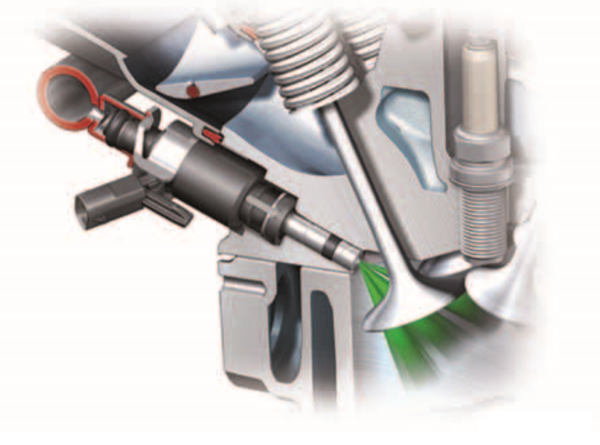

OEM DI Injectors: The high-pressure fuel is delivered to the high-pressure fuel injectors These injectors sit on the intake side of the engine under the intake manifold. These injectors are pulsed for a maximum of half the engine cycle (so only around 50% duty cycle) because you can’t inject during the power and exhaust strokes unlike a port injected car. The fuel injector pulse windows shrinks as the engine speed increases and if the HPFP pressure drops, they have to open for longer still to compensate for the lower pressure. Because of this you can see OEM injectors become limited at both peak torque (due to the HPFP dropping pressure) and peak horsepower in the upper RPM due to the limited opening time. They too generally run out of headroom around 400WHP and 400WTQ.

How to Upgrade the OEM Fuel System

LPFP Upgrade – With nothing else added this can get you about 20-30 WHP at the top end. The 450 LPH (liter per hour) pumps can supply enough fuel for around 550WHP and most are E85 compatible. If you are looking to push above this there are 525 LPH LPFP as well. Upgrading the LPFP requires tuning changes or running an external controller to prevent the OEM ECU controller from overheating. We recommend tuning for any fuel upgrades with something like a Cobb Accessport and custom tune.

HPFP Upgrade – This upgraded replaces the internals of the HPFP with a larger bore pump. An HPFP upgrade increases the amount of fuel delivered per stroke and can prevent the pressure from dropping at peak torque. A HPFP on its own will give you an extra 20-30 Ft-lbs. of torque headroom in the mid-range and is E85 compatible.

After you have replaced the HPFP and LPFP you have gained the capability to comfortably run E85 fuel on most IS38 bolted cars year-round and have fueling headroom for 420-430 WHP and WTQ.

After you have replaced the HPFP and LPFP you have gained the capability to comfortably run E85 fuel on most IS38 bolted cars year-round and have fueling headroom for 420-430 WHP and WTQ.

However – there is a better way!

MPI – Multi Port Injection. If your ECU and tuning solution support adding port injectors, you only need to add an MPI kit and an LPFP upgrade for a practically limitless fueling solution.

With some mild modifications to your manifold, adding MPI allows you to add 4 injectors to the manifold of the MK7 GTI and R to provide port injection.

In addition to providing additional fueling, an MPI system will have the added benefit of port cleaning and a low side fuel pressure sensor which allows you to both read how your LPFP is performing in real time and to control the LPFP pressure.

How To Choose your Fueling Upgrades:

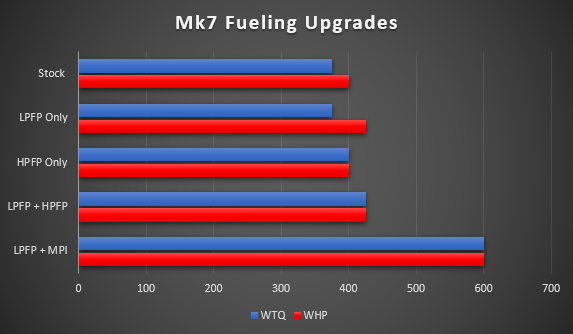

The stock fuel system of the MK7 will get you up to the 400 WHP and 380-400 WTQ range.

If you are looking to just hit around or just above 400WHP/WTQ range, you can achieve that with just the HPFP upgrade.The HPFP upgrade alone is good to run on E30-E50 IS38 setups year round and full E85 IS20 setups.

HPFP and LPFP upgraded together will be sufficiency for full E85 setups on IS38 cars.

Beyond that it is recommended to get the MPI kit with an LPFP (You can leave the OEM HPFP in place).

When sizing your MPI port injection kit – 700WHP can be reached with 980cc injectors and up to 1000WHP with the 1300cc injectors.

For the LPFP the 450 LPH LPFP will support up to 550WHP or there is the 525 LPH option if more is needed. Most cars over 600+whp may consider surge tanks and upgraded lines.

We recommend running MPI with an LPFP upgrade if you want to run hybrid or larger turbochargers on E50+ ethanol mixtures. MPI also keeps your intake valves clean AND gives you the low pressure side readings and control over pressure in real time. This makes this setup the most robust and with the most features.

We recommend running MPI with an LPFP upgrade if you want to run hybrid or larger turbochargers on E50+ ethanol mixtures. MPI also keeps your intake valves clean AND gives you the low pressure side readings and control over pressure in real time. This makes this setup the most robust and with the most features.

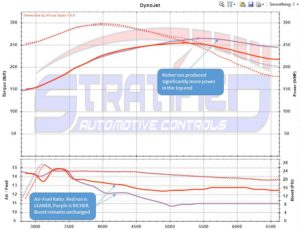

Below we break down the relative power potential of the different permutations.

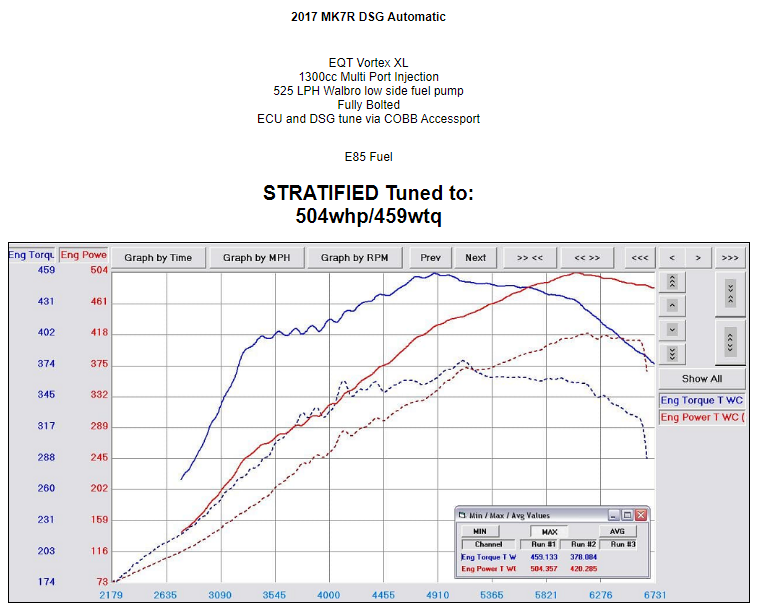

Below you can see an example of a car that is we tuned using the COBB Accessport with a bigger turbo, upgraded low side fuel pump and a MPI kit making 500+whp.

Below you can see an example of a car that is we tuned using the COBB Accessport with a bigger turbo, upgraded low side fuel pump and a MPI kit making 500+whp.

Hope this helps you choose your fuel modification path and Happy Tuning. Get in touch if you have further questions.

The Stratified Team

*Pictures sourced from Volkswagen Service Training Manual for the 2.0L TSI Engine.