VW has been using an electronic diverter valve (DV) on their turbo TSI/FSI engines for a long time. This is a hotly discussed topic in the community as the valves sometimes fail and VW has several revisions of the valve.

As many of you know the purpose of the diverter valve is to vent excess boost when the throttle is closed (you lift off the accelerator or change gear). Without venting this excess pressure, the turbo experiences surge which is actually damaging to the turbo. You can hear this as a fluttering sound.

Due to this it is very important for the DV to function properly. By the same token, when the throttle is open and you are building boost, this valve must stay shut and not vent boost from the high pressure side to the low pressure side. Venting this boost under wide open throttle causes a boost leak and a drop in power.

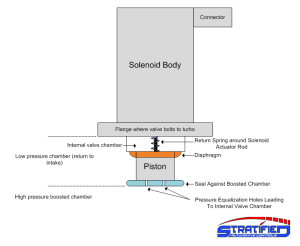

Let’s start with the basics and outline the components of the valve:

The valve in the image above is known as Rev G of the valve and it is found in the earlier Audi and VW cars. Before going any further we have to discuss just how the valve works. All the electronic valves work on the same principle so this applies to all of them.

The light blue piston seal at the bottom of the valve presses against the high pressure side opening inside the compressor housing. This seals the high pressure chamber from the low pressure chamber that connects to the intake right in front of the turbo. This connection between the high and low pressure is all inside the turbo compressor housing and the DV either allows air to pass or not between the two pressure areas.

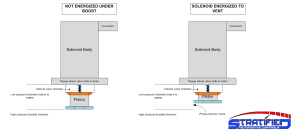

The top of the valve houses a solenoid that pulls the piston up when energized opening the valve. The spring helps return the valve to the sealed position and also keeps the valve closed as boost builds up.

Here’s where things get interesting. The spring is much too soft to prevent boost from pushing the valve open. Because of this VW has designed a set of holes at the bottom of the piston shown below.

These opening allow boost pressure to build insider the internal valve chamber. This chamber is sealed from the low pressure side by the orange diaphragm. This pressure that builds up inside the valve equalizes the forces on the valve and keeps it shut under boost. Once you lift off the throttle, the solenoid pulls the valve open (with a good amount of force and speed) releasing pressure to the intake from both the charge piping as well as the internal valve chamber. The spring then returns the valve to the sealed position.

So how do these valves fail?

One obvious failure mode is a tear in the orange diaphragm. Once the diaphragm is torn boost will leak from the internal chamber to the low pressure side and the piston itself won’t be held shut as tightly.

VW/Audi have built a more robust valve with the Rev D pictured on the left below. This valve does away with the diaphragm that is prone to failure. There is more to it than just this.

Boost leaks and undesirable valve “lifts” happen during transients. That is when you are just building boost, or when you are quickly back on the throttle after a gear shift. During times like these one of two things can happen:

One is that the valve does not return quickly enough to the seated/sealed position. The stiffness of the spring along with the mass of the piston determine this speed. The Rev D valve has a stiffer spring and a faster returning piston.

Secondly, the piston can lift if the internal valve chamber does not fill quickly enough with pressurized air due to the pressure imbalance. You will notice that the Rev D valve has more openings (6 versus 4) than the older valve allowing for faster pressure equalization.

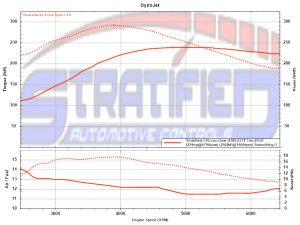

Keep in mind that if the valve does not seal or lifts when it’s not supposed to, you are likely to not just experience low boost, but also a low boost code (P0299). You are also likely to hear a high pitched noise under high boost if you have an aftermarket air intake installed.

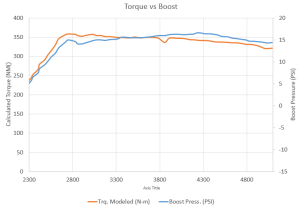

If you experience the error code, intermittent boost, or loud whistling, it’s time to check your DV. Upgrading to the Rev D valve can address some of the reliability issues of the older diaphragm based valve. However the Rev D also has potential issues. One is that it doesn’t have a good seal against the compressor housing potentially allowing some boost to leak. Another is that the spring may still be too soft when you are building boost in excess of 25psi quickly.

There are several aftermarket options out there. The key is to have the fastest acting valve with the least amount of surge that still seals. The ECU monitors pre-throttle boost and can also trigger fault codes if the valve is not fast enough or too stiff and there are pressure spikes in the charge piping so keep this in mind. As always, it’s all about building the right solution for your specific needs.

If you have any questions or would like to discuss options and tuning, don’t hesitate to Contact Us.