In light of recent questions I have been receiving, just wanted to discuss the design choices behind our recently released Xtra fuel system.

First of all, when talking about fuel delivery more is not always better. You want to have as much fuel as you need with a little bit of headroom but you don’t want an under-utilized fuel system. The reason for this is that too much actually hurts driveability and performance.

The biggest reason for this is resolution and the fact that injectors are actually mechanical pieces with defined opening and closing times. Injectors are actuated electronically but inside them there are small needles that lift when the ECU turns them on to spray and this is called the injector PW. There is a delay time for them to lift and for fuel flow to stabilize. Usually this delay for port injection injectors is 0.8-1.2 milliseconds (ms). Within this time, the injector is not spraying or the spray is not well atomized. This can cause very uneven delivery from stroke to stroke and air/fuel ratio fluctuations. You can see this kind of phenomenon in older school high horsepower builds where the cars idle very rich and high. These problems are addressed with staged injection system and this is exactly what this Xtra Fuel System is.

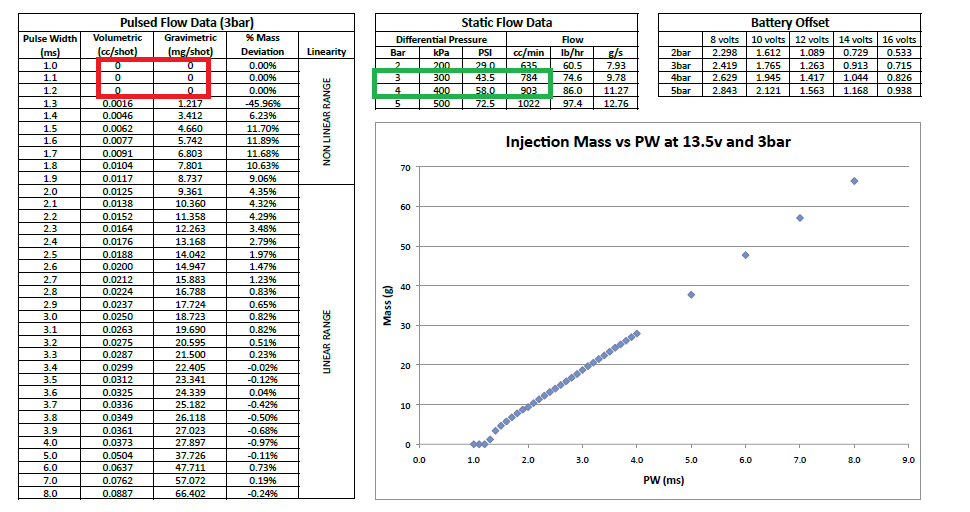

Attached is the injector flow data from the injectors used in our kit. I highlighted in red the area where the injectors are opening – you don’t want to operate them in this region! I highlighted in red the flow region in which we are operating at 30psi of boost and 80psi of fuel line pressure.

With the injectors we have chosen the minimum pulsewidth we are running them at is at 1.6ms. The maximum PW we run them at to cover 30% of our total fuelling at 415whp on our shop car is 3ms. This means that any more injectors or any bigger injectors will be difficult to control in terms of pulsewidth eventually not being able to open reliably. Remember that this system has to blend with the OEM DI system in a smooth and predictable manner.

The next question is – are these two injectors big enough for your needs? At 3ms opening time, the two injectors are ran at a whopping 35% duty cycle cycle at 8000 RPM. This is while the aux fuel system covers 125whp worth of fuel. To get to 600whp we need to cover 600-375 = 225whp with the aux system. Let’s take some more stress off the OEM system and we are looking at covering 250whp worth of fuel. At that rate we will need 70% duty cycle from the aux injectors. There is still headroom in the system even at that power level with an 80-90psi rail pressure.

One more thing to keep in mind. Always use as much of the DI system as possible for your power needs. The entire control system in the Focus is built around an efficient DI system so use it to its full potential. This means that the aux system should only be used at WOT and only used as much as there is need. Otherwise, again, driveability, economy, and poor running will result.

These kind of design decisions and A LOT of on-vehicle testing have guided the design of this system and the choice of components used. It’s easy to fall into the trap of “overbuilding.” The best way to maximize performance is building to YOUR power needs. A little headroom is nice. A lot of headroom hurts a lot more and really doesn’t help.

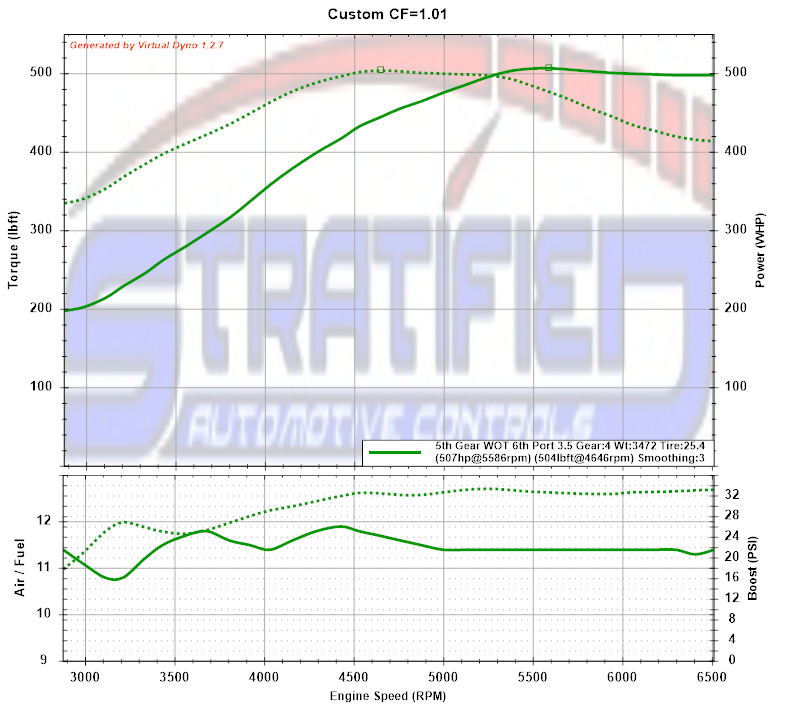

While the big power builds on the Focus are just starting to happen, we have plenty of experience with a similar but slightly older platform and these aux fuel systems. Here’s the result of a two injector throttle body aux injector system we tuned on a MazdaSpeed3 with a GTX3071 turbo making 500whp.

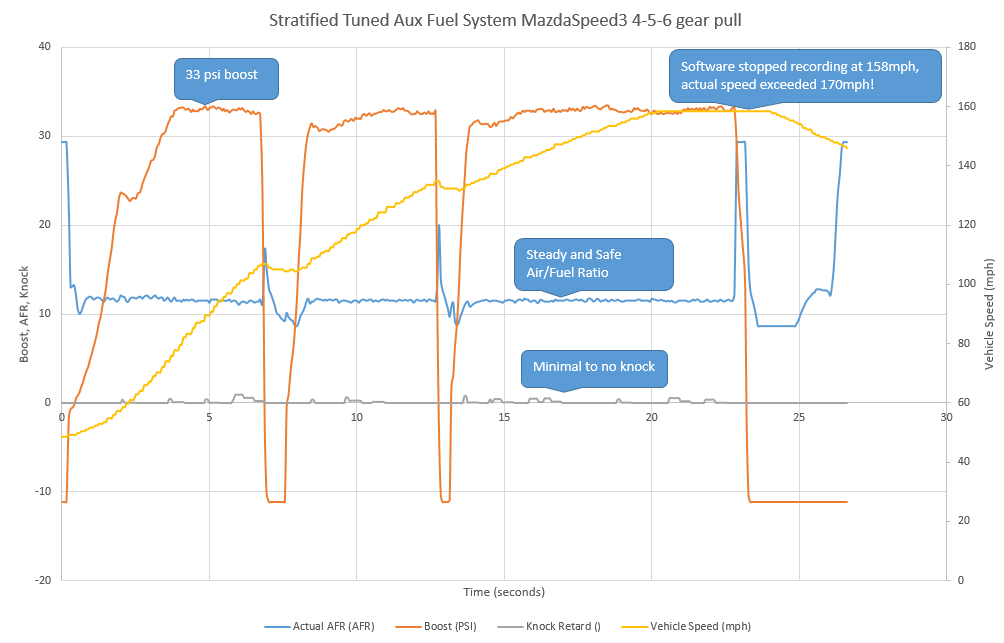

And yes, reliability is there. The proof is in this datalog where the car is driven at WOT to the top of 6th gear (on a closed course)!

If you have questions regarding whether this system is right for your build and power level don’t hesitate to contact one of us on the Stratified team and we are more than willing to answer any questions.