The Ford Ecoboost knock detection system is one of the more complex systems out there. A lot of the vehicles using the Ecoboost engine are rated to use fuel that ranges in octane from 87 to 93 octane. Because of this, Ford built a system that is very powerful and adaptive. It actually learns your fuel quality while you drive. All the EB engines we work with use this adaptive timing system. This is great for us calibrators as we can build failsafes and adaptability into the tunes – but it has to be setup correctly.

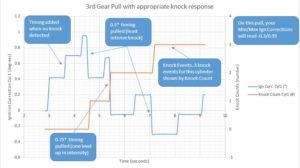

The knock detection system starts with the sensors (microphones) that pick up engine noise and are mounted to the engine block. If the engine noise falls within the correct frequency and window of operation (around the time the spark plug fires), the ECU registers this as knock. When knock is registered, the ECU looks at the Knock Response table pictured below. Based on the intensity of the knock it subtracts timing advance from the Ign. Corr. Cyl X Parameter (which you can view and datalog) on a per cylinder basis. On each knock events it also increments the Knock Count Cyl X parameter which can also be viewed. Both of these parameters are reset to 0 once you let off the throttle, shift gears, or experience a throttle closure.

Keep in mind that the following ECU tables shown have OEM values. We adjust these to better suit our performance criteria, but the principles remain the same.

The amount of timing being pulled for each knock intensity and engine speed is completely under the control of the tuner who builds the tune. You want to make sure that you pull enough timing per knock event to maintain engine safety and stop the knocking. Here’s how this looks in a graphed datalog of a single cylinder during a pull.

These negative ignition values are always subtracted from the current Ign Corr. Cyl X variable for each cylinder. This is important to understand because the Ign Corr. Cyl X variable also ADDS timing when the system does not “hear” any knock and you are on the throttle.

The rate at which timing is added and how much total timing is being added is also adjustable in the tune. Ideally the tune should walk timing up at a reasonable rate that is not so fast such that knock is induced and not too slow such that performance is left on the table.

One thing that has to be understood is that all engines will knock at some point regardless of tune and fuel used. The combustion process is a chaotic process and sometimes you get some irregularities. This is inevitable. You want to tune out heavy and sustained knocking, but completely eliminating all knock is not something that is realistic – especially in a street engine. Handling knock correctly is the key. Light knock will NOT damage an engine especially if timing is reduced via a reduction in Ignition Corrections when it happens. LSPI (Super Knock) and bouncing off a Rev Limiter have a MUCH more damaging effect on the pistons and rods.

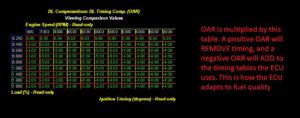

The beauty behind this knock control system that both adds and subtracts timing is that it also LEARNS the quality of your fuel over time. The learning variable is called OAR (Octane Adjust Ratio). This variable is like a fuel trim but used for ignition and load/boost targets. It can range from -1 to 1. Below is the table that allows the ECU to learn and adjust OAR. You can see from this table that in order for this system to work, ignition timing and the Knock Response table must be set such that the ECU can ADD and SUBTRACT enough timing to make the Ign. Corr. Cyl X parameters positive as well as negative during a pull. With an adaptable tune you are likely to see Ign. Correction numbers that are both positive and negative at times.

Finally, this OAR number is not just another pretty face. It affects the timing AND load/boost tables the car will be targeting. An OAR that is closer to 1 will remove both timing and boost reducing future knocking. An OAR closer to -1 will add timing and boost due to good quality fuel and increase performance. It is normal for OAR to fluctuate slightly depending on your fuel quality and driving conditions (5th gear pulls are more likely to knock compared to 3rd gear pulls and OAR will adjust to reflect this). Below is the timing table that is multiplied by OAR in the OEM calibration and added to the overall ignition timing the ECU runs. In this case an OAR of -1 will add 4* timing and an OAR of 1 will remove 4* of timing near redline. OAR dependent boost/load limits are setup via a blend of several tables not shown here.

It should be clear now that NEVER seeing any negative corrections is an indication of a tune not setup to use this learning system to its full potential. This is not ideal on a street driven car as it means that it will not adapt to keep the engine safe when fuel quality or driving conditions change nor will it extract more performance when the situation allows.

Keep in mind that these knock detection systems are extremely fast to react. If knock is detected, if setup correctly, the system will very quickly pull timing to stop the knocking during that pull and adjust the tune for future pulls. Excessive repeatable knock or only positive ignition corrections are something that should be addressed in the tune – and can only be done by the person that has set the tune up. More on knock in this article.

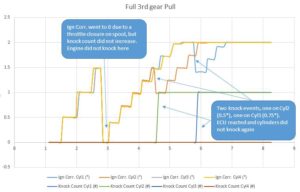

Now let’s have a look at a set of logs see this in action across four cylinders.

Here’s a normal 3rd gear pull with all 4 cylinder Ign Corrections and Knock Counts graphed. As you can see, ignition timing walks up when there is no knock in a step-wise fashion. When there is knock it drops down stopping further knock. If the knock events happened earlier in the pull or were of a higher intensity, Ign Correction could have become negative.

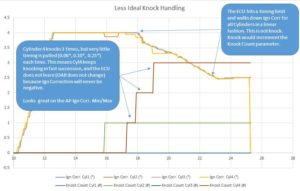

Here is how we can setup the same knock detection system in a less ideal manner. At first glance, it looks like this engine is basically not knocking at all. However if you look carefully, you can see that there were 4 knock events. The amount of timing pulled for each event is very little. This does two things. One, not enough timing is being pulled to stop the occurrence of further knock. Secondly, pulling so little timing will mean Ign Correction values will not be negative even though the engine could be knocking heavily and continuously. This in turn will mean the OAR will not adjust and the tune will not adapt to the fuel quality used.

For this reason, watching Min/Max Ign Correction on the AP can be very misleading. Not only does it not show you how many times the engine knocked, it also doesn’t show you how intense the knock was. To determine the performance of the tune, a full datalog is always necessary or at least a good understanding of HOW the tune handles knock events.

Happy Tuning,

The Stratified Team