This is a scenario I have seen a few times and I think it is worth going through and the implications of blowing the pressure signal hose off your wastegate or EBCS.

First of all, this is a very dangerous scenario. In most cases a single event like this will either damage or blow the OEM motor. The most dangerous part of this is that it is UNCONTROLLED and pressures rise much too quickly. This is why we have created our Guardian Angel. It is great insurance for this scenario.

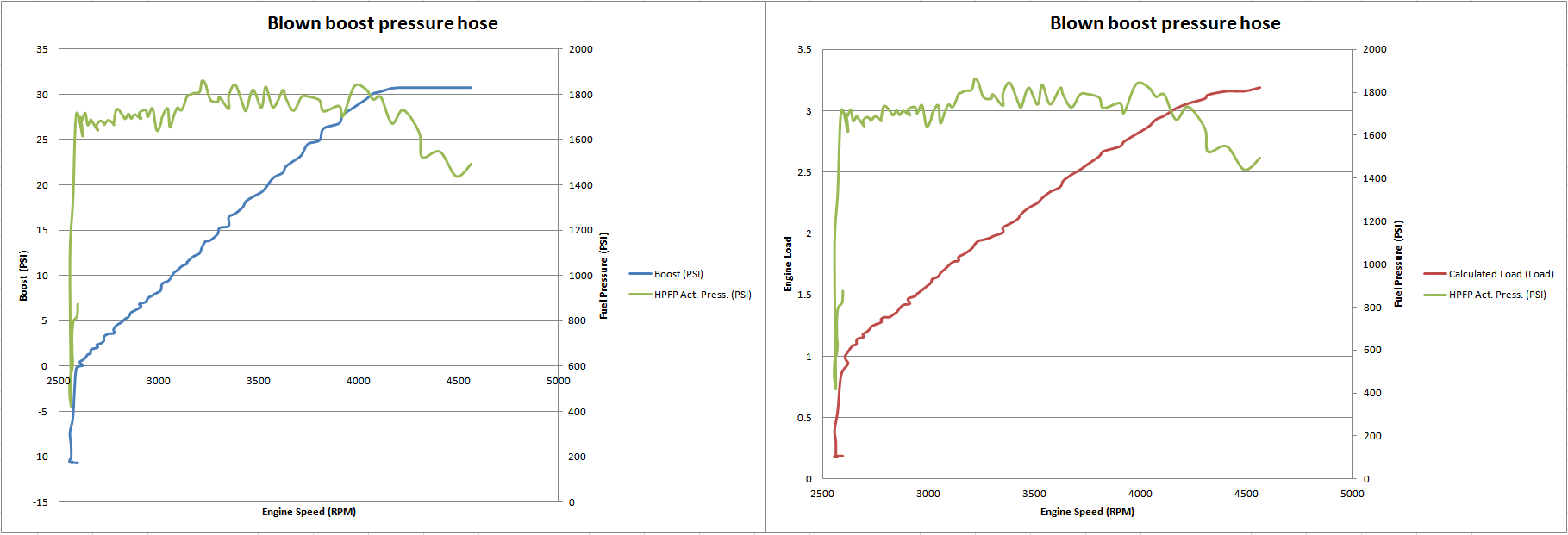

Below is the event shown graphically. This is a car running a GTX3071 with a 3 port COBB solenoid and the hose blew off the solenoid barb. The barbs are really small on these solenoids – this is why we went with 1/4″ barbs on our 3 Port. Better to struggle pushing the hose on than have it blow off or leak.. The same thing would happen if the hose blew off the wastegate port.

You will see boost rising in the left hand graph until it pegs the 3 Bar MAP sensor and it continues rising past this. The boost cut in this car is set at 25psi and you can see that it took over 1000 RPM of being above 25psi in 4th gear for the ECU to cut.

During this time, load (airflow) continued increasing and you can see this in the left hand graph exceeding 3.0 load by 4100 RPM and exceeding 100% injector duty by 4400 RPM. At the point where 100% injector duty was reached the limits of the Autotech internals (or perhaps in-tank pump) are also reached and fuel pressure starts to dip before the ECU initiates the cut.

This is a harsh way to see just how much airflow the GTX3071 can generate (a lot!) as well as where the limits of the fuel system lie in the low end. Thankfully, he was on E85 and the engine stayed together this time but it’s not certain if anything was tweaked internally. I estimate boost exceeded 35psi before the ECU cut based on extrapolating past where the sensor was no longer able to read.

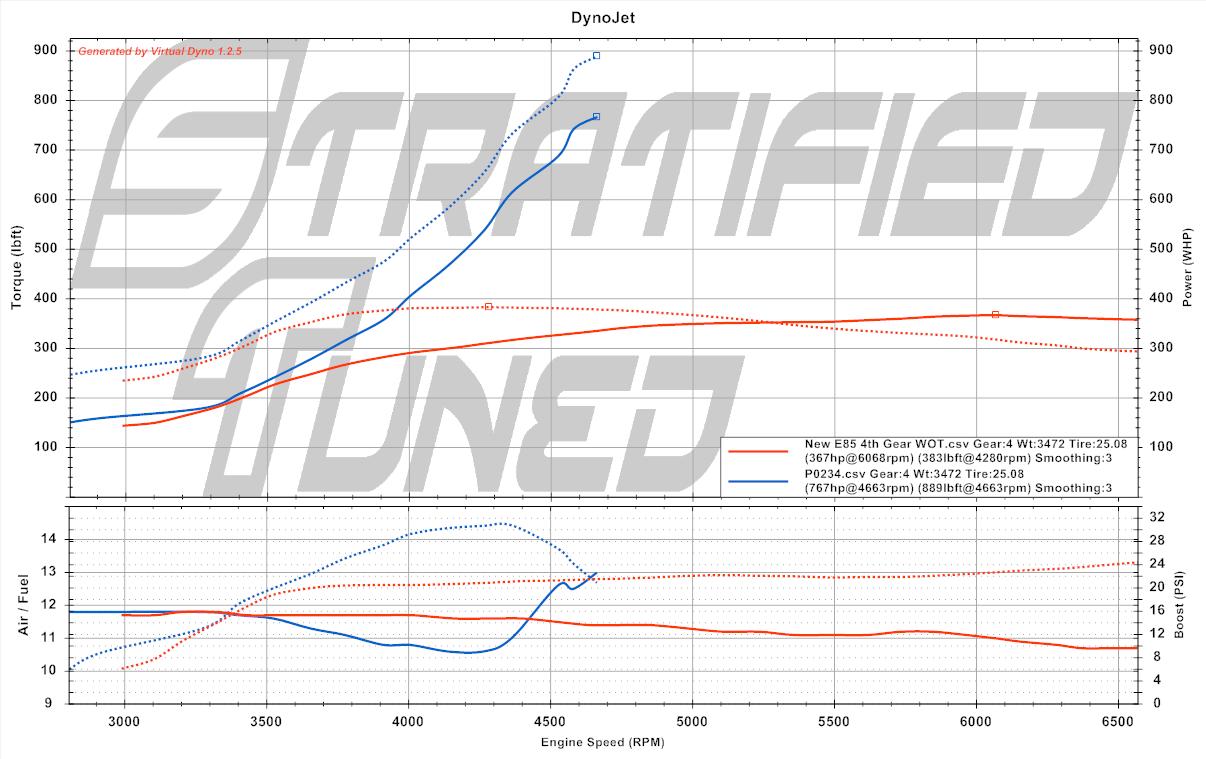

What does this look like on Vdyno next to a controlled 4th gear pull? Yes, there probably was some wheel spin but you get the idea.

To avoid this there are several important steps:

1. Use proper hose clamps and not zap straps (zip-ties) around hoses. Zap straps will either not apply enough pressure or melt and beak in high heat areas.

2. If the barbs are mismatched in size, either get an adapter or different barbs, or a solenoid with properly sized barbs.

3. If you are altering the hoses or boost control system in any way from OEM, the Guardian Angel is highly recommended. It is very cheap compared to a blown motor due to a single mishap. It protects you from mechanical as well as tuning errors.