As the power levels rise for the Ecoboost powered cars, there is a need for additional fuelling over what the OEM system provides. Choosing the correct fuel solution for your needs is important so this 3 part series of articles will walk through how the OEM system works, when you need to upgrade, and finally, what the correct upgrade is for you.

So let’s start with the basics and look at how the OEM Ecoboost fuel system works. As you know, the car uses a direct injection fuel system that pressurizes fuel to above 2000psi (we can and do target higher pressures but as soon as flow drops so does pressure – more on this later) before injecting it directly into the combustion chamber. The fuel system is made up of the following components:

An in-tank returnless transfer pump (LPFP). This pump is electronically controlled via the tune and it can operate at pressures of up to 100psi. On the Focus ST, this in-tank pump can flow up to around 475whp worth of fuel. From all the OEM fuel system components this is the highest flowing component and the last to run out or need an upgrade. It sits inside the tank in an assembly that looks like this: Moving from the tank there are 5/16 fuel lines that travel under the vehicle and up towards the rear of the engine bay. As the lines enter the engine bay there is a low pressure fuel sensor that you can monitor via the COBB Accessport or similar device. This sensor is what the ECU uses to target the desired LPFP fuel pressure and you can use to see the health of your LPFP

Moving from the tank there are 5/16 fuel lines that travel under the vehicle and up towards the rear of the engine bay. As the lines enter the engine bay there is a low pressure fuel sensor that you can monitor via the COBB Accessport or similar device. This sensor is what the ECU uses to target the desired LPFP fuel pressure and you can use to see the health of your LPFP

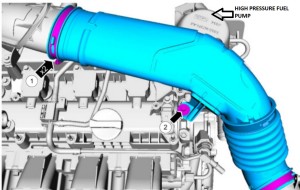

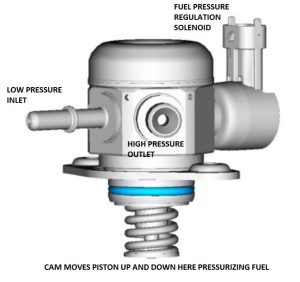

This feed line is then connected to the inlet of the HPFP (high pressure fuel pump). This pump is driven by the exhaust camshaft of the engine. In the 1.6 and 2.0 EB engines the camshaft has 3 lobes. On the 2.3 (Mustang EB, Focus RS) it has 4. So for every single revolution of the camshaft (every two revolutions of the engine) the pump is actuated 3 (or 4 for the 2.3l) times.

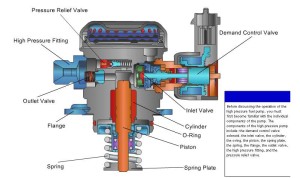

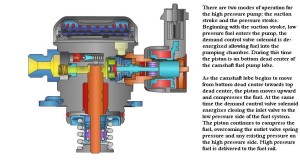

The pressure is controlled electronically via a solenoid inside the pump and via the ECU/tune. But keep in mind that the pressure is also related to the amount of fuel FLOW the pump can deliver. And this is a function of how quickly the pump piston is move up and down, the amount of fuel moved during a single stroke of the piston, and the inlet fuel pressure of the pump. On the EB motors, the HPFP is the first to run out of fuel flow, especially at low engine speeds (because the camshaft is also moving slowly) Below is more on the fuel pump operation for those interested.

Below is more on the fuel pump operation for those interested.

The high pressure fuel is then delivered to the high pressure fuel injectors and the fuel pressure is measured by a sensor on the fuel rail. These injectors sit on the intake side of the engine. They are the second part that will run out of flow on the various Ecoboost engines. However, they do so AFTER the HPFP and this is a key thing to remember. Without upgrading the HPFP, higher flowing injectors won’t be of help by themselves.

The high pressure fuel is then delivered to the high pressure fuel injectors and the fuel pressure is measured by a sensor on the fuel rail. These injectors sit on the intake side of the engine. They are the second part that will run out of flow on the various Ecoboost engines. However, they do so AFTER the HPFP and this is a key thing to remember. Without upgrading the HPFP, higher flowing injectors won’t be of help by themselves.

So to recap, the OEM fuel system consists of an LPFP in the tank (good for 475whp on the 2.0l), an HPFP driven by the exhaust cam (good for 380 ft lbs of torque and 370whp on the 2.0l) and a set of injectors (good for 380-390whp on the 2.0l). The 1.6l runs out of fuel around 50whp earlier and 2.3 has around 30-40whp extra in hand. Part 2 of the article in the series will go over how to tell if your fuel system is in need of an upgrade and some of the issues that come with direct injection fuelled engines. Part 3 will go over the solutions and how to stay safely fuelled. Stay tuned!