The Fiesta ST (FiST) is an excellent handling car. Not very often do you have front wheel drive (FWD) cars handle as well as the Focus and Fiesta STs. There are several things that make the Fiesta stand out in spite of it having quite a conventional and simple suspension layout (with a solid rear axle!).

One of the advantages the FiST has over the competition is its light weight. There is little that can make as much of a difference as shedding weight. The reason for this is that changes in direction (changes in momentum) require a lot less energy. This in turn translates in less energy lost between the tire contact patch and pavement, less energy lost in compressing the suspension, flexing the chassis, etc. The second great thing about the FiST is the way the suspension was setup from the factory. It is a stiff suspension for a production car; but this is what us enthusiasts crave. Finally, let’s not discount Ford’s torque vectoring. This little trick allows the chassis ECU to independently apply the brakes to any wheel in order to make the car rotate and apply power more effectively in corners. This is something used in the Focus ST and RS as well. All of this adds up to a car that is very happy to handle the turns and that means fast lap times!

Is there a way to improve on this already great recipe? With some careful planning there is! What you want to avoid is to take away some of the rotation happy characteristics of the car. That means that I recommend leaving the sway bars alone initially; especially on a car this light. Instead focus on grip (tires, alignment) damping (shocks) spring rate (springs), and brakes.

Coming to the shocks and springs discussion; I always recommend upgrading to something with the best shocks. Springs are simple compared to the shocks and the ride quality as well as handling bumps and corners almost always comes down to the shocks. A personal favourite is Bilstein for me. They have a reputation for making great shocks and whether you get a B8 shock + spring combo or one of their coilovers you’re in for a treat both on the street and track. We recently installed a set of B14 Coilovers on our 2015 Fiesta ST and they have been great. We have these same coilovers on our 2014 Focus ST as well. Very affordable combined with great performance makes the B14 a go-to option when upgrading the suspension. From our experience – here are a few install tips for the Fiesta ST:

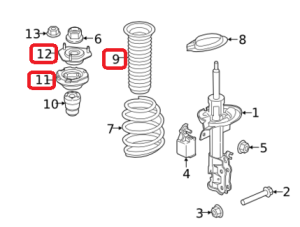

- Purchase the top hats (PN C1BZ3A197D), front strut bearings (PN 8V5Z18198A), and dust boots (PN 8V5Z18A047A) (these act as a spring insulator as well) from the dealer before embarking on the job. You will need two of each. They are affordable, make the assembly of the front suspension a breeze without needing a spring compressor, and they are wear items that should be replaced when upgrading the suspension.

- When installing the front suspension, push the front strut assembly at the strut tower towards the inside of the car before tightening it down. This will give you the most camber you can get without camber plates. Camber is a good thing.

- When installing the rear shocks, before bolting them to the chassis apply some grease to the top of the bushing (you will reuse the OEM one) and clean the chassis and mounts. If you don’t do this you will hear squeaking from the rear suspension when driving.

- When setting up the ride height, allow the car to have a bit of rake and don’t “slam” it for best performance. You want to look at the front control arms and allow them to be relatively flat with the pavement.

- Get a professional alignment to set the front toe, make sure the steering wheel is straight so you won’t get poor tire wear.

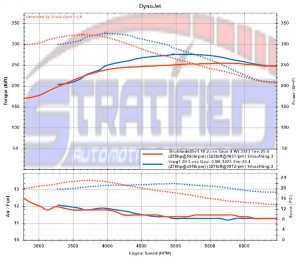

After this get out there and enjoy the car. The ride will be a little stiffer but should feel compliant and not jarring. You will notice less brake dive and less body roll. The car should have very good turn in and still be very very happy to rotate. We’ve taken the car to autocross with just this suspension change (and our COBB AP and Tune) and it proved to be one of the fastest cars there … even putting a few expensive German sports car to shame.

It should be mentioned that this Fiesta has a few other modifications installed and these give it more pull out of corners with excellent throttle modulation and control and a nice induction sound.

For tires, there are lots to choose from out there. Because the car is so light you can get away with tires that are a little less extreme than what most use for the same application. The tire wear will also be good, again, because of the light weight. The OEM tires are good and you can work your way up from there. Even for an open track day you can do very well with a set of extreme summer tires such as the Bridgestone RE11/RE71, Dunlop Direzza and others in that category. Those tires would also be great for auto-x as they come up to temperature relatively quickly.

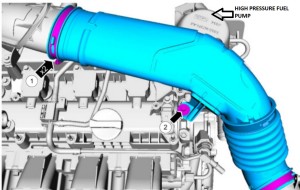

To improve handling further on our particular car, we are looking at tires and brakes next. Engine performance wise, the next steps would be an upgraded intercooler and/or WMI, and some exhaust work. These should maximize the power potential (and sound) of the stock turbo before thinking about upping its size just a bit … Stay Tuned!

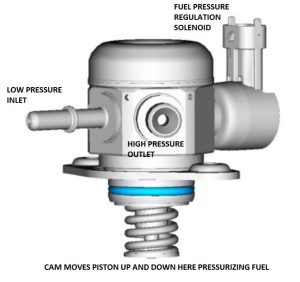

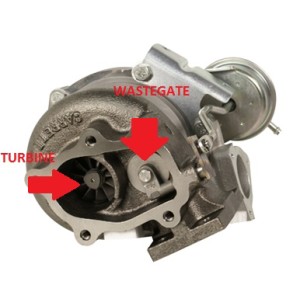

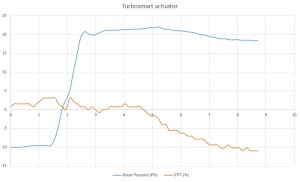

other indication of the lack of efficiency of the K03 at those boost levels. The higher we pushed it in terms of boost, the more negative the trims.

other indication of the lack of efficiency of the K03 at those boost levels. The higher we pushed it in terms of boost, the more negative the trims.