Having had a MazdaSpeed3 from 2008 and having been involved with the platform for so many years, one of the most common question that I’ve received – especially in the early days – was why do engines blow on the highway? I went as far as having a collection of broken parts from blown engines all over the country just to see how they failed.

This was a new phenomenon and we saw lots of cars that were bone stock blow up – especially with the first generation MS3 and MS6.

It turns out the Mazda was a pioneer back in 2005-06 when it introduced the DISI – one of the first direct injected spark ignited motors on the market.

Recently (since about 2010-11) the tGDI (turbo gas direct injected) engine has become common so it has received a lot more attention. As more money was spent in downsizing and increasing power output the failure mechanisms in these motors started to become more clear.

And these failures line up exactly with what we are seeing with the DISI.

The root cause is a phenomenon called Low Speed Pre-Ignition (LSPI).

LSPI, which results in Superknock, is auto-ignition before the spark but not early enough to melt the piston. It happens close to the spark event and causes massive knock afterwards. Damaging knock.

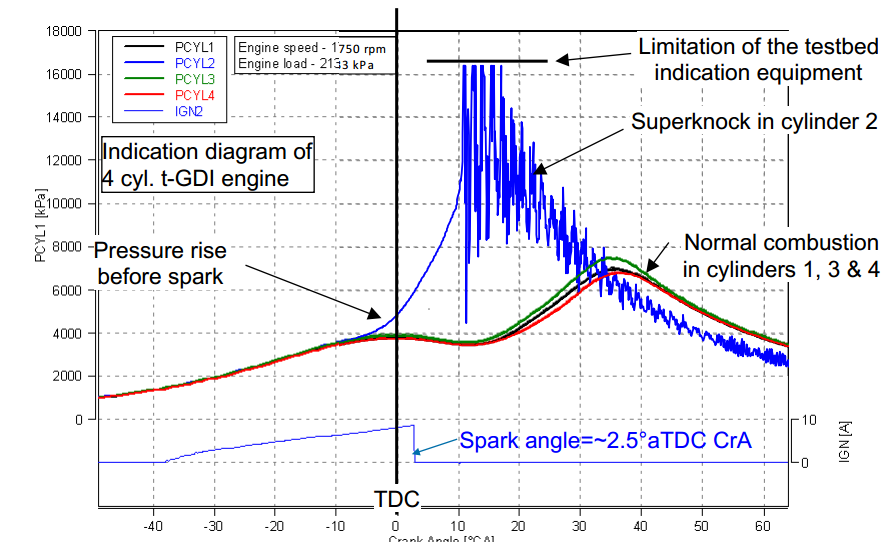

The other interesting fact about LSPI is that it happens at low engine speeds and high loads which is a common condition when passing on the highway, for example. Below is a graphic showing the knock in the cylinder just after LSPI occurred:

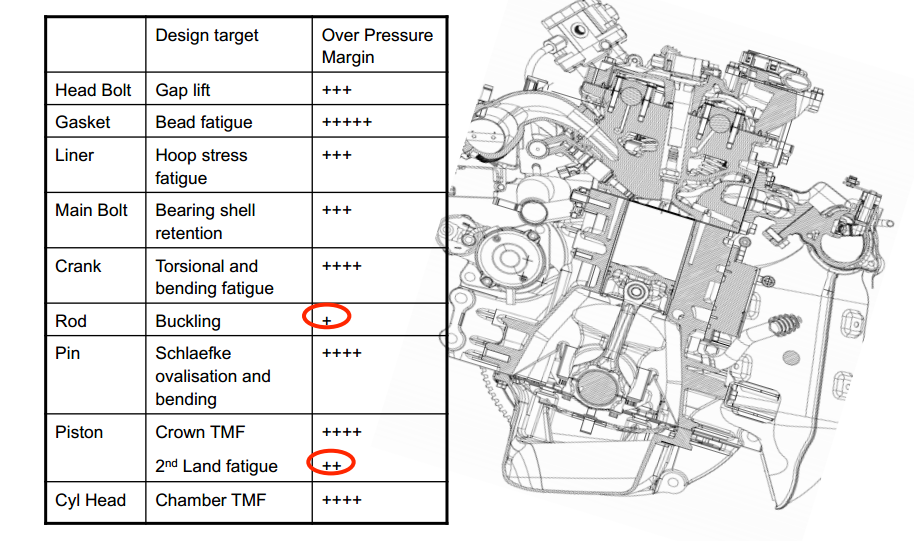

LSPI is hardest on the rods and pistons in the motor. The rods tend to fail first, and the second ringland follows. This is exactly what we have seen in the MazdaSpeed DISI. Further, most people that lose their motors on the highway or have high knock events on the highway speak about a cloud of black smoke. This is also caused by an LSPI event. From the SAE paper 2011-01-0342:

“From exhaust emission and exhaust port air/fuel ratio measurements it was also recognized that a spike in HC emissions and a significant increase in Lambda (air/fuel ratio enrichment) was associated with LSPI”

Now why does this happen?

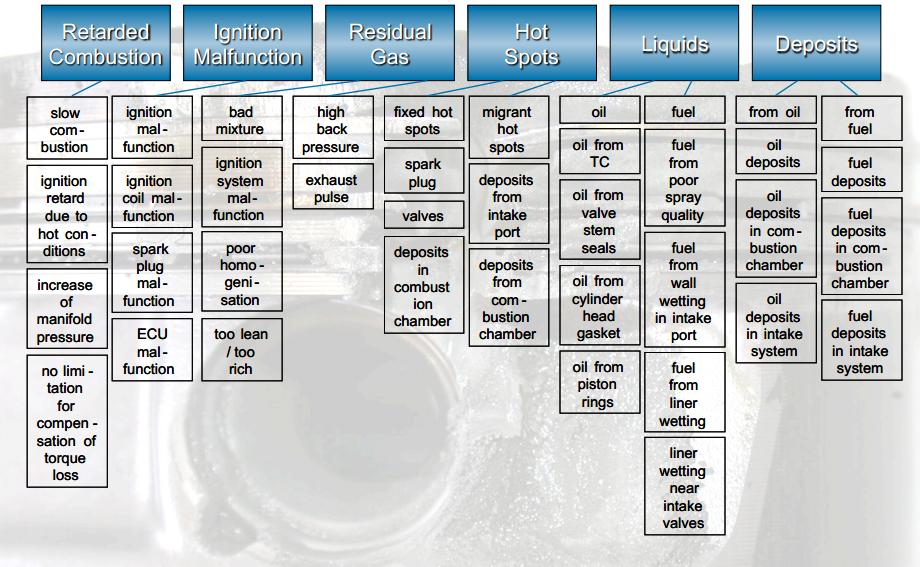

There are a number of factors but the biggest are:

– Carbon deposits on pistons and valves, oil fumes, poor quality fuel

– High loads at low RPM

– Valve overlap, EGR

All the causes are still not known. This is still a heavily researched area.

A more complete list below:

The OEMs have learned a lot since the DISI. Take the Ford Ecoboost for example, it doesn’t toss rods like the DISI did. However we have seen it damage pistons and ringlands from the same LSPI phenomenon numerous times. The EcoBoost is an evolution of the DISI using the lessons learned from the early days of tGDI engines.

So what can be done to prevent this condition?

– Don’t operate at high loads and low RPM (Instead of loading the motor at a low RPM, downshift into a lower gear)

– Use quality fuel and lubricants (lots of research going on in this area currently)

– A good tune

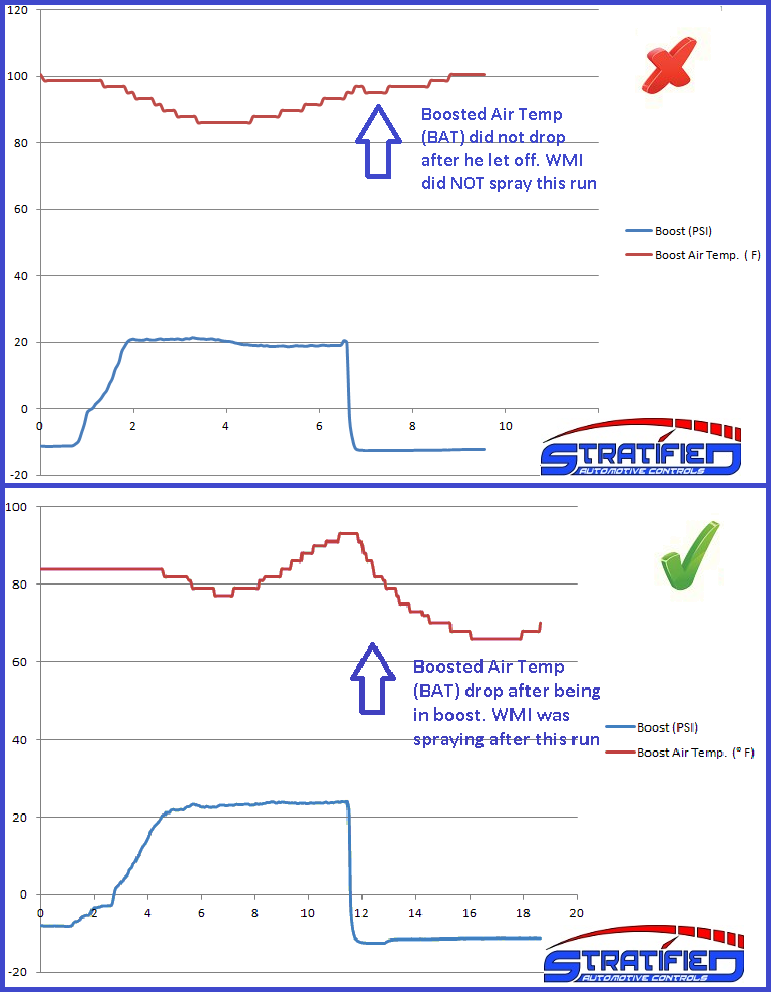

– Good intercooling (the TMIC really doesn’t help here on the Mazda), WMI if available

– Good operation of the PCV system, clean intake and valves

– Step colder plugs to prevent hot spots

– Keep oil consumption down – use a thicker oil if needed

The manufacturers have greatly improved piston, injector and combustion design since the DISI. You can even see that Mazda redesigned the pistons in the Gen2 (after 2010) and LSPI was less common on the newer cars because fuel was not washing down the walls of the cylinder as much.

Using common sense can keep the DISI together for many miles, but determining WHY cars blew on the highway has been a very interesting journey for me and it feels like the root cause is finally becoming clearer.

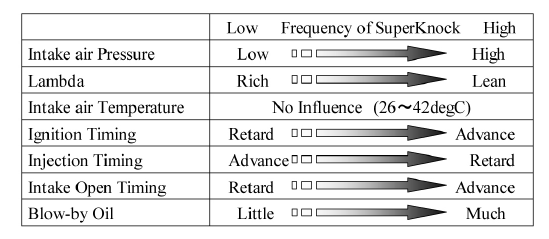

Keep in mind that there is never a single variable that will make a motor come apart and every motor will behave slightly differently. This is good because you can attack different areas of your build to prevent LSPI and superknock. Below is a good summary showing some of the engine parameters and their effect on triggering LSPI.

Not all engines fail due to LSPI. The rods do buckle at certain torque levels and knock can be damaging at higher engine speeds, not just at low speeds. However that strange phenomenon with engines letting go on the highway very much lines up with LSPI being a failure mode in DISI engines.

The images are from a good presentation at the link below. There is a lot of SAE literation on the topic if you’d like to learn more about it.

http://www.ukintpress-conferences.co…_Alewjinse.pdf