We here at Stratified are often asked what are the best plugs to run in our modified cars. The answer to this question depends largely on the primary use of the vehicle, and the extent to which it has been modified.

TL;DR: Buy your NGK LTR7IX-11 plugs on our website HERE.

When changing spark plugs in your vehicle there are two things to consider:

1. The spark plug gap:

This is the easier of the two considerations; for the Ford Ecoboost engine found in the Focus / Fiesta ST as well as the DISI in the Mazdaspeed vehicles we always recommend a plug gap of 0.025 – 0.026″. It is important that the plug be properly gapped or else the car will miss fire under boost/load. A larger gap produces a larger, hotter, spark which helps increase combustion efficiency, however, the larger the gap the harder it is for the ignition system to send a spark across the gap. This is especially evident in the Ecoboost and Mazdaspeed motors which run high boost levels and sparking resistance increases with increased cylinder pressure. Conversely, if the plug gap is too small then the spark created may be too small/weak to properly ignite the combustion mixture.

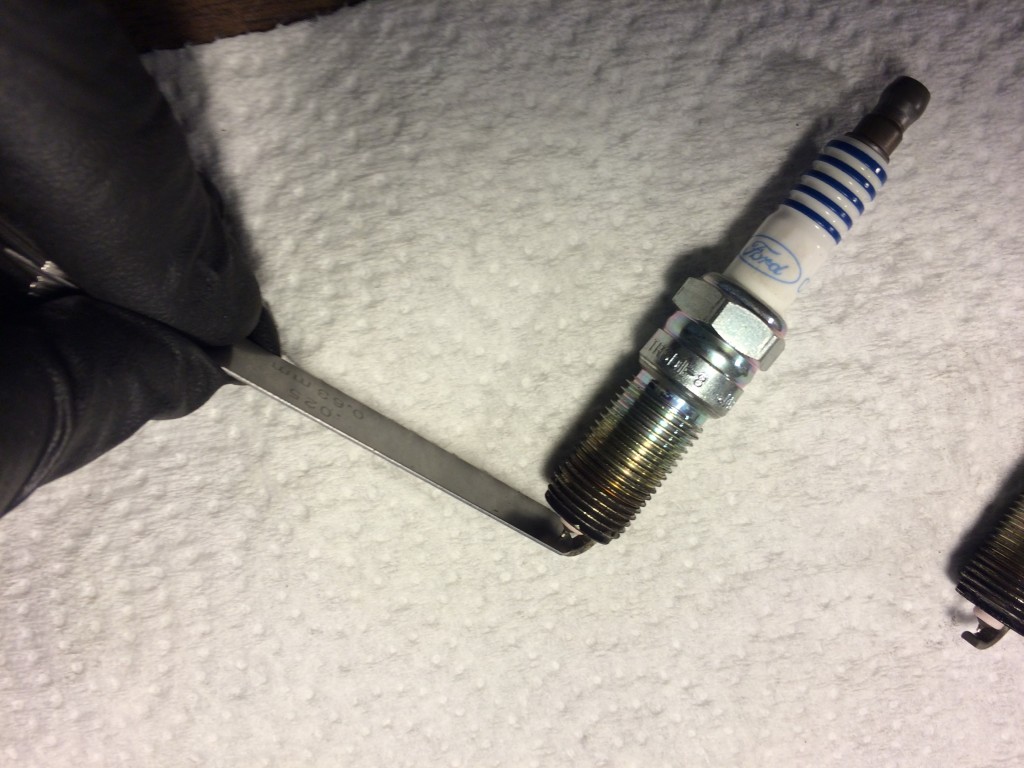

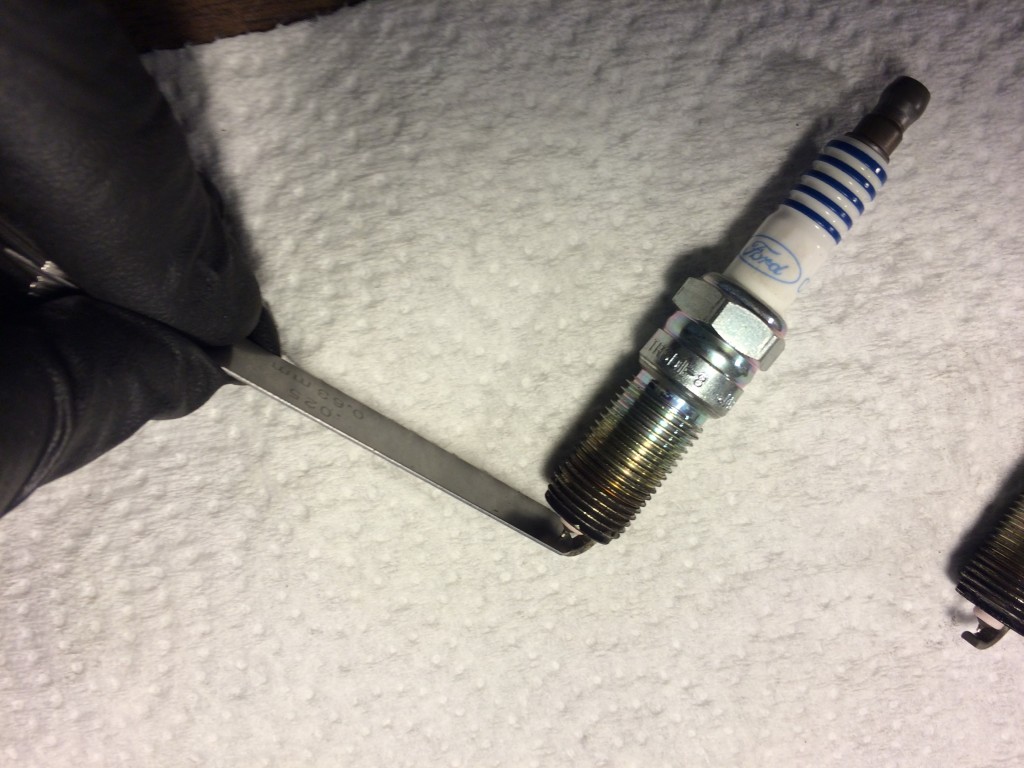

Most plugs for the Ford ST and Mazdaspeed vehicles come with a gap that is larger than our recommended 0.025 – 0.026″, thus it is necessary to lessen the plug gap. When checking your gap it is important to use proper feeler gauges; you’ll know you’re at the right gap when the feeler passes through the gap with minimal resistance. When closing your plug gap it is important that you do not push up against the plug’s centre electrode as it is easy to damage. The recommended gaping procedure is to tap the ground electrode against a hard surface such as a vice or sturdy shop table several times and then to recheck the gap. You will quickly get the hang of this.

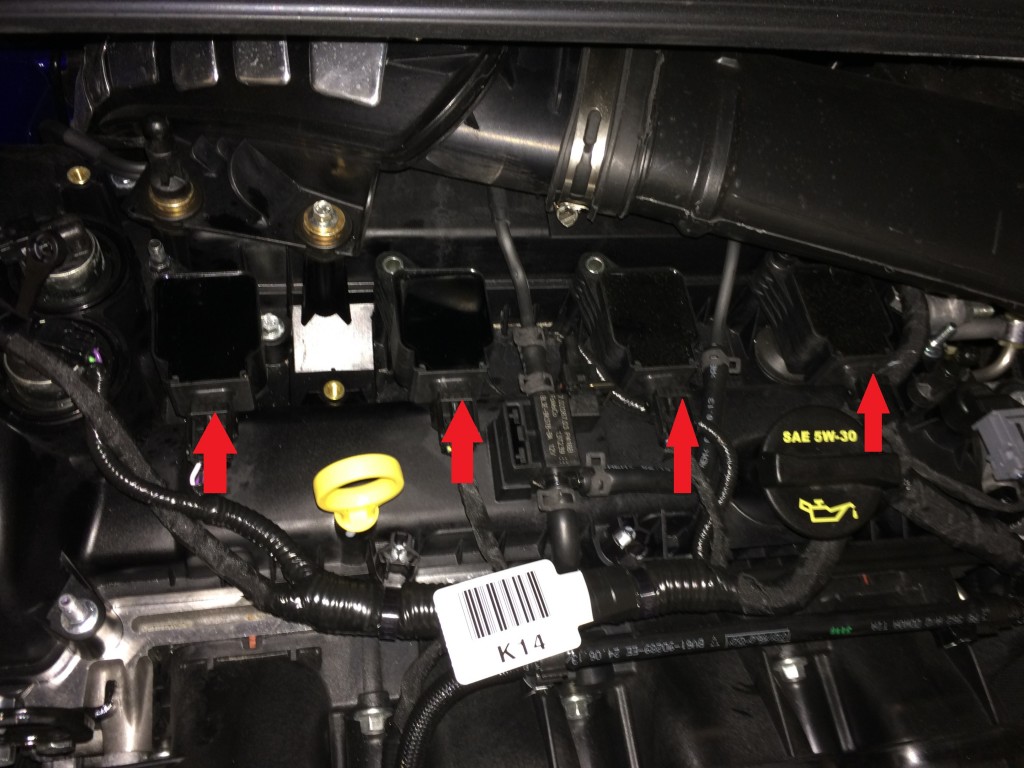

The proper tool to measure your plug gap:

Tap the ground strap down gently checking the remaining gap often:

When the feeler gauge passes through without catching you know you’re at the right gap:

The spark plug gap will generally widen as the spark plug is used. This is due to the erosion of the ground strap but also due to the strap experiencing heating and cooling cycles. If you start to experience misfires and it’s not time for a plug change yet, pull the plugs out to check and re-adjust the gap as necessary.

2. The spark plug heat range:

This is where your modifications, and primary use of the vehicle come into play. Cold plugs are better for highly modified engines, while hotter plugs are more reliable on a daily driven vehicle. If you primarily use your vehicle for low speed daily driving or allow it to idle for extended periods of time, then a cold plug may foul. If you race your vehicle or repeatedly expose your engine to sustained high loads then a hot plug may cause pre-ignition which often results in a melted piston.

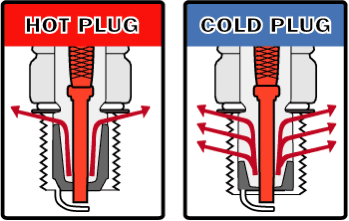

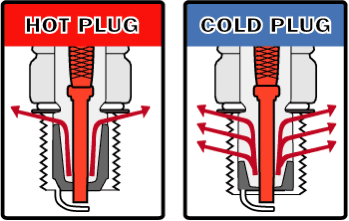

Now you may be wondering to yourself “What does the heat range even represent?” A common misconception is that a hotter plug produces a hotter spark; this is not true. The heat range boils down to how much heat the plug dissipates into the cylinder head. The pictures below provide a good representation of the spark plug heat range:

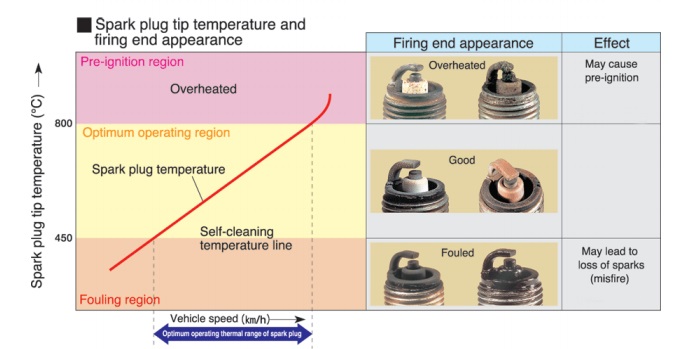

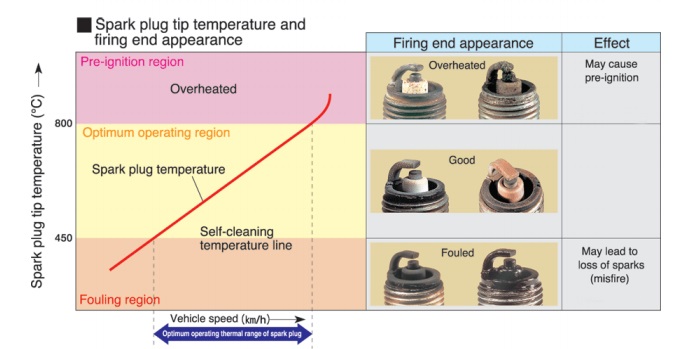

As you will notice, the hotter plug has a much longer portion of the insulator nose exposed to the combustion chamber. This longer nose goes hand in hand with a reduced surface area for the heat transfer. Since hotter plugs leave less area for this heat transfer to occur the firing end will get much hotter. This reduced heat transfer is necessary when your vehicle is driven slowly or often idled for long periods of time as it helps keep the spark plug at optimal operating temperature (which prevents fouling). However, if the plug chosen is too hot then the insulator tip may become overheated during spirited driving. Once the insulator tip reaches temperatures of around 800C (1470F) it can (will) act as a pre-ignition source (think of a glow plug on diesels) lighting the mixture long before the ECU initiates the ignition event. Pre-ignition is the silent killer of engines; once it occurs there is no sound (knock sensor does not become triggered), there is no warning, only melted pistons/plugs. Due to advancements in engine design pre-ignition is not very common in modern street vehicles.

On the other hand, if the plug selected is too cold then the insulator will never be able to reach its self-cleaning temperature of around 450C (840F) and carbon deposits will start to accumulate on the insulator nose, leading to a fouled plug. Fouled plugs will misfire causing a loss in power and fuel economy. Furthermore, the built up carbon on a fouled plug could start to ember as insulator tip temperatures begin to rise during spirited driving (for example going to a track day, or a canyon run). This embering carbon build up is again an ideal pre-ignition heat source. As you can see going both too cold and too hot can be detrimental.

Another consideration with the heat ranges is cold starting. A plug that is of a colder heat range may have a harder time starting your vehicle when the temperatures start to drop.

Keep in mind that if you are having any doubts about your spark plug health it is possible to “read” your plugs. The appearance of the firing end can tell you a lot about your plug’s operating temperatures as well as the health of your engine. Below is a graphic showing what it is you need to look for. If you are running a colder than OEM plug and it is carbon fouled then you should return to the OEM heat range. If you manage to overheat a plug and haven’t killed your engine then we recommend going at least a step colder.

Another way to check whether the plug’s heat range is correct for your motor is to check the annealing point on the ground strap. If the heat range is correct the annealing line should be around the beginning of the ground strap bend. If the annealing is occurring too close to the electrode then you know that your plug is too cold. If the annealing occurs far down the ground strap bend then the plug is too hot. Here are a couple of pictures of some healthy OEM plugs with around 3,000 miles on them from the Stratified Focus ST development car that were replaced with a step colder plug along with the downpipe, intercooler, and intake (and some tuning of course!). Notice how the colour of the ground strap starts to change right at the beginning of the bend; looks like Ford did their homework!

In conclusion, too cold or too hot of a plug is detrimental. There is a misconception that a plug will cause knock and this is generally not the case. If a plug is to do long term damage, it is pre-ignition and that is not picked up by any knock sensor but also dangerous and thankfully, fairly rare on both the MazdaSpeed and Focus ST/Ecoboost platforms.

In conclusion, too cold or too hot of a plug is detrimental. There is a misconception that a plug will cause knock and this is generally not the case. If a plug is to do long term damage, it is pre-ignition and that is not picked up by any knock sensor but also dangerous and thankfully, fairly rare on both the MazdaSpeed and Focus ST/Ecoboost platforms.

For the DISI motors we recommend running a spark plug that is one step colder than OEM. Generally the Mazdaspeed motors do not like running plugs that are two steps colder than OEM unless very heavily modified. Cars that are running higher compression, large amounts of boost, or are often tracked / driven aggressively for extended periods of time may at times require a plug that is two steps colder than OEM (for example have an extra set of colder plugs for track days).

For the Ford Ecoboost we still recommend a plug that is one step colder than OEM for mildy bolted cars especially since 21+psi of boost is quite common. For highly modified cars that see a lot of heat it is advisable to try a plug which is two steps colder than OEM. The Ecoboost motors seem to be able to manage colder plugs better than the Mazdaspeed motors.

For both the MazdaSpeed DISI and Ford EcoBoost the recommended plugs are either the NGK LTR7IX-11 or Denso ITV-22.

Remember to not forget to change the plugs when worn and to not overtorque them when installing.

Happy Tuning,

The Stratified Team

Photo Credits:

Heat Ranges and plug conditions – NGK TECH

Hot Vs Cold Plugs – Hot’N’Cold