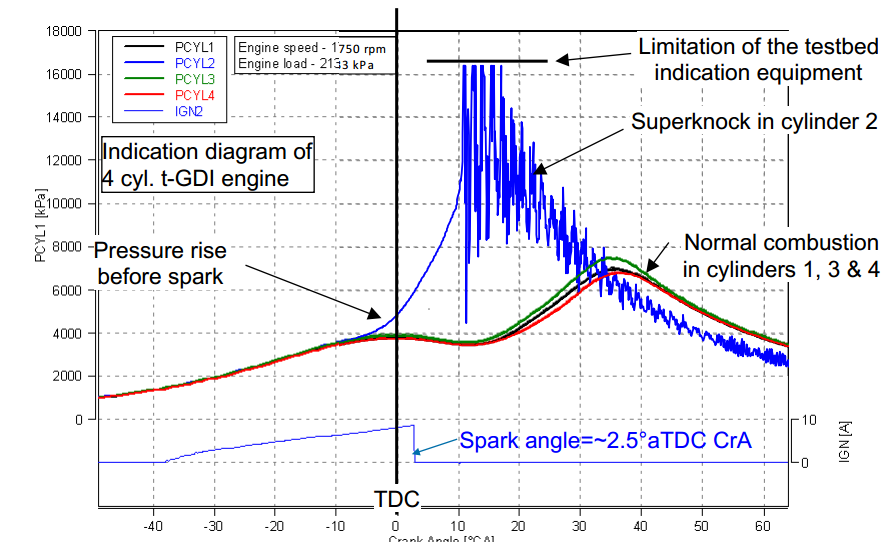

All engines knock! Ok, now that that’s out of the way :). Knock or detonation is a phenomenon where the combustion process does not start at the spark plug and propagate completely smoothly pushing the piston down. Instead, there are several small flame fronts that usually appear at the edges of the main flame front during the power stroke. These smaller uncontrolled explosions cause pressure spikes in the combustion chamber. High enough pressure spikes for a long duration can cause damage so naturally we want to avoid high intensity knock in our Ecoboost cars … but not completely eliminate knock … Let me explain why. Or … just jump to the end of the article for a quick list of what to look for.

Modern cars such as the one above have well tuned “microphones” called knock sensors that pick up on these sounds and react very quickly to stop detonation when it starts. The 4 cylinder Ecoboost has two of these little guys:

When the ECU detects knock it reduces ignition timing advance. Back in the day when the knock sensor technology was not advanced engines knocked all day long without immediately blowing up. You could hear them pinging going up hills. These days, we push small engines to make a lot more power and we realize that maximum power is made right at the knock threshold. Another way to say it is that we want to keep the engine RIGHT at the edge of knock and the modern ECU in the Ecoboost does exactly this through some smart programming.

The ECU always listens to the knock sensors and knows which cylinder is knocking while it keeps adding timing. Once it starts to hear knock it reduces ignition timing on a cylinder by cylinder basis and eventually it learns an ignition trim that scales the entire ignition table up or down depending on how much knock it picks up. This trim is called the OAR – the Octane Adjust Ratio. Over time, the closer this value is to -1, the more timing the ECU is adding to the base timing table since the fuel is good and it is not picking up much knock. The closer it is to +1, the more knock the ECU is picking up meaning either the octane you are using is poor or the tune is too aggressive or both. So having a peek at your OAR using a logging tool such as the COBB AccessPort ever so often will give you an idea of the fuel quality and how the tune is behaving. ***Keep in mind that the tuner has the ability to adjust how the OAR parameter learns so in some cars OAR will sit at one value and in others it will move around more. If you have concerns, bring it to their attention.***

Using a logging tool such as the COBB AccessPort during a wide open throttle (WOT) run can give you further insight. After datalogging such a run you can look at two parameters to get a good idea of how the tune and fuel are performing. These parameters are knock count for each cylinder (how many times the particular cylinder knocked) and knock intensity for each cylinder (how much timing was pulled during each count – called Ign Corr.) When ignition correction is adding timing, that means no knock is heard by the ECU. When it is pulling it back in a step down fashion, it has done so because it heard knock in that one cylinder.

Keep in mind that the way the ECU reacts to knock is tunable. Some tuners will have the ECU pull a good amount of timing when the severity is higher while others are more aggressive. We like to stop knock the first time we hear it so in Stratified tunes the ignition corrections are larger so that knock does not continue happening in that cylinder.

This is something to discuss with your particular tuner. Once you get familiar with what you’re seeing in datalogs you will know what is and isn’t normal. It is also important to choose a tuner that is experienced with the ECU and how it adjusts timing to get the most from this feature without risking the safety of the motor.

In terms of knock counts – remember that when it’s not knocking the ECU is adding timing until it knocks or until it reaches a ceiling for amount of timing added. Because of this, you are likely to get some knock counts during a pull if the tune is built to maximize performance.

Ideally the tune is setup such that knock event intensity is low and that the tune adds timing in a way that doesn’t cause a lot of sudden knock. It’s normal to see the ECU add a little timing and take some away. What you don’t want to see is very large, multiple, and continuous negative ignition corrections.

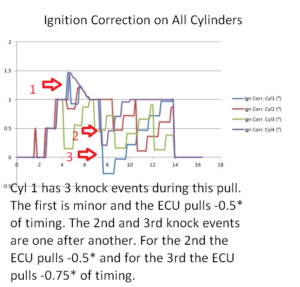

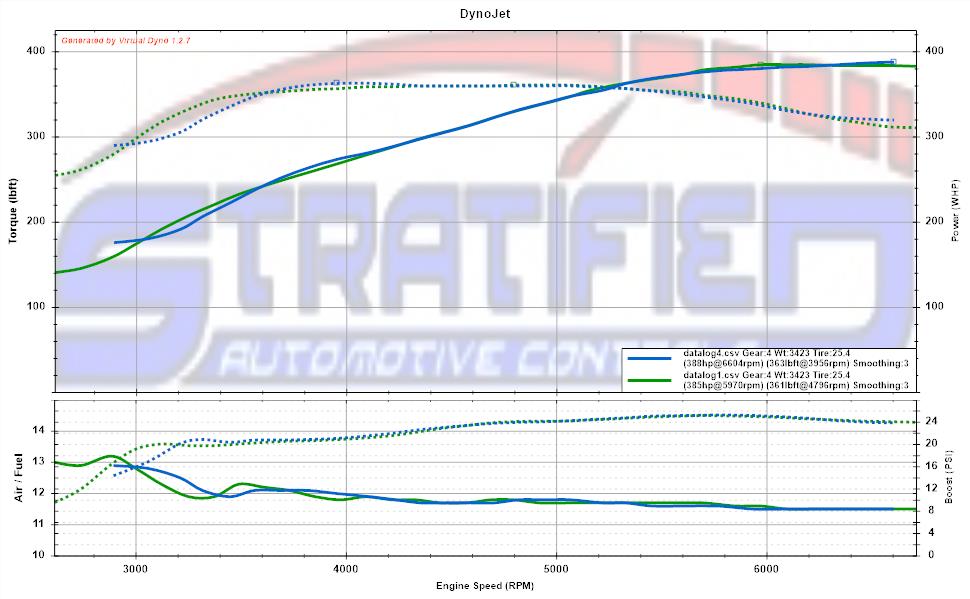

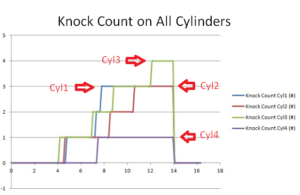

Let me give you an example. Below are the knock counts on a 4th gear pull for cylinders 1-4. This tells you that some knock has happened during the pull but it doesn’t tell you anything about how severe/intense it was. This is incomplete information. You can see here that Cyl1 knocked 3 times, Cyl2 knocked 3 times, Cyl3 knocked 4 times, and Cyl 4 knocked only once.

To complete the information here are the cylinder ignition corrections for the same pull. As you can see below Cylinder 1 has 3 knock events labelled on the image. The most severe correction was around -1.0 degrees of timing on cylinder 1 and right away that cylinder added more timing and didn’t knock again. You can also see that each cylinder walks ignition up a little, then steps down when it reaches knock. Finally, you can see all the cylinders are well balanced. There isn’t one cylinder that is significantly better or worse than another one. The tune on this car is running well and it is fine tuned for the vehicle’s modifications and fuel.

Also note that there will be differences from pull to pull and this is again normal. Always take a couple of pulls to make sure the data is consistent.

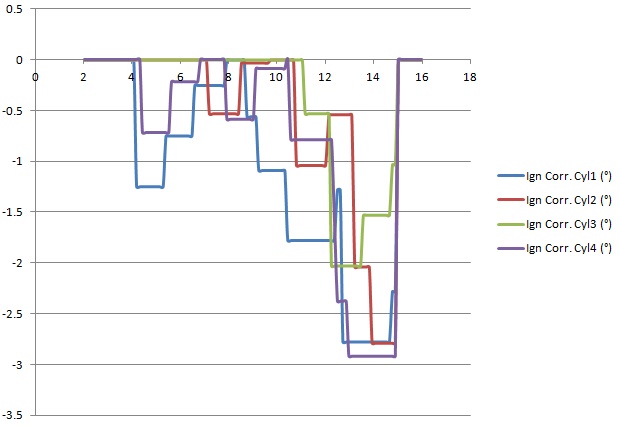

Here is a tune that needs attention or the car is using poor quality fuel. You can see that all the cylinders move into the negative ignition correction zone and some with larger steps meaning that the ECU is picking up knock and lowering timing. Also notice that the ECU pulls timing to avoid knock (a step drop in correction); but the engine knocks again (several more steps down). You can also see that they are not recovering like the graph above (not many steps upwards)

Here’s a summary on what to keep an eye on. Keep in mind that looking at min/max ign corr. values does not tell you the whole story. Looking at a datalog of a full RPM sweep and looking at knock counts together with the ign corr value. tells you the information you need:

- Do ignition drops happen regularly at the same RPM and is it consistent at that RPM and boost?

- The car ADDS timing unless it hears knock. When knocks is heard you will see a DROP in ignition correction. This drop can make ignition correction negative or it can stay positive depending on what the starting value is. If ign corr. is at +3 and there is knock event, it can drop to +1 for example. If it is at 0, it can drop to -2. The knock that it heard is actually the same, the size of the drop tells you how intense the knock event was. The larger the drop, the more intense the knock.

- Every time you see a drop, it means knock was detected and the ECU dropped timing to protect the engine.

- Stratified tunes tend to drop ignition timing quite a bit when knock is detected the first time. This is to prevent further knock in the pull and to keep the engine safer. Always look for the NUMBER of drops, (knock counts) not just the Ign Corr. Value.

- Multiple drops in ignition correction at the same RPM and across multiple cylinders likely mean that you may need the tune touched up or need to use better quality fuel. We can do this remotely for you using your datalogs.

This car does not instantly blow up when it experiences some knock. Far from it. However if you see consistent knock, either higher octane fuel is needed or the tune should be adjusted.

Happy Tuning,

The Stratified Team