This is a topic that is very active among automotive enthusiasts and is also relevant to the work we do in the Stratified office. If you do not already know this from experience then you must know: Knock (also known as pinging or incorrectly referred to as pre-ignition/pre-detonation) is a major limiting factor to safely increasing the power output of your motor. Knock occurs after the spark event begins combustion and is the spontaneous combustion of the remaining combustion mixture. Ideally once spark has occurred the intake charge will burn in a smooth manner outwards from the spark plug until the flame front is finally quenched by the cool cylinder walls. When knock occurs your engine experiences a sharp rise in pressure and temperature. If severe knock is occurring at high loads, it may lead to engine damage. Due to this we are limited in how much boost and timing we can safely run. An in depth analysis of knock is a topic for another discussion but it is important that you know of it’s existence and the limitation it imposes on performance. Every motor will eventually knock (with enough compression, timing, boost, etc), however, the goal is to use a fuel that safely and consistently supports your desired power output.

So knock is bad, what can we do about it?

Aside from cooling your intake charge via a bigger intercooler, water-meth injection, or a cold air intake, increasing your fuel’s octane rating is the best way to push your motor’s knock threshold up. High octane fuels are less likely to auto-ignite which is what makes them better for high performance applications. E85 has an octane rating that is much higher than the 93 octane most premium gasoline fuels provide. The octane increase benefits from E85 are applicable to any motor. Running 100% E85 is possible in vehicles where the fuel systems are built for E85 (Flex-Fuel vehicles) and where the fuel system can deliver larger volumes of fuel than what is needed with regular gasoline fuels. This is due to E85’s increased oxygen content and lower energy density. On the Mazdaspeed DISI as well as the Ford EcoBoost motors we do not readily have larger direct injection injectors and the fuel pumps are not designed to handle straight E85. Because of this we blend E85 with premium pump gasoline to achieve a mixture that is both compatible with the OEM fuel system while delivering higher octane. We have seen excellent results from an overall mixture of E30. This mixture is accomplished by mixing premium fuel (which usually contains 10% E85) with E85. The mixture should be 25% E85 by volume to net an overall mixture of around E30 (this is due to the premium fuel’s ethanol content).

Okay, ethanol is great, what kind of gains does it provide?

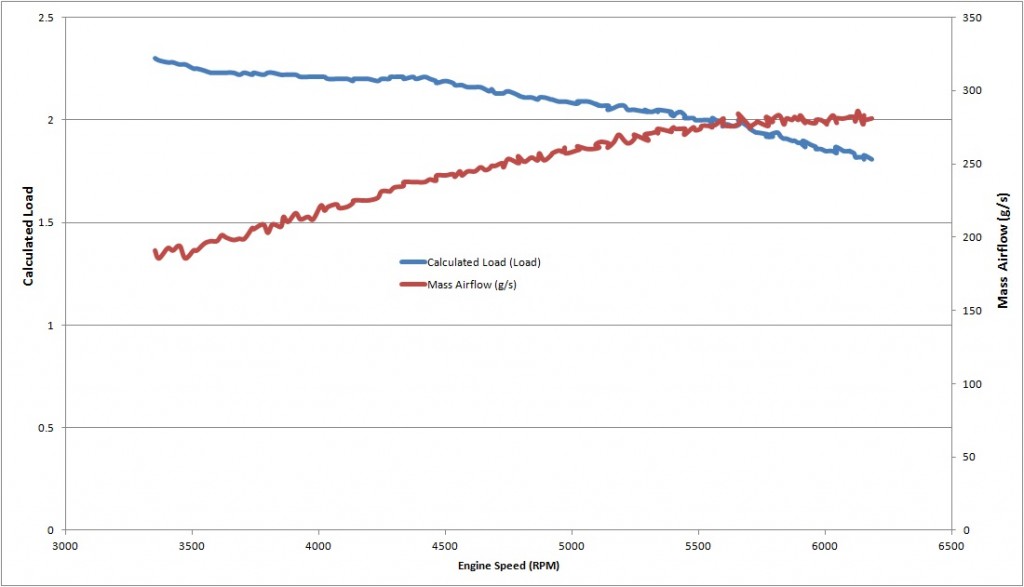

The gains we see from running ethanol blends in the EcoBoost and DISI motors will vary from case to case, however, they are always significant. The performance gains from an ethanol blended fuel will change depending on the base fuel used and modifications installed. For vehicles running the OEM turbo (K03 Ford, K04 Mazda) the average gains are on the order of 25 WHP and 25 WTQ for the Mazdaspeed DISI motors and 20 WHP and 20 WTQ in the Ford EcoBoost motors when going from a pump gas to E85 tune. If your vehicle has a bigger turbo then it will really shine with an E85 tune. As the airflow increases and temperatures start to climb the added ethanol really works to bring down cylinder temperatures and help keep knock away. Below are a few graphs which highlight the differences between E85 and gasoline tunes.The gains we see in these graphs come from the increased timing and boost we can push thanks to ethanol’s higher octane and increased cooling properties. In order to see these types of gains it is necessary to get a tune which is designed for ethanol blends.

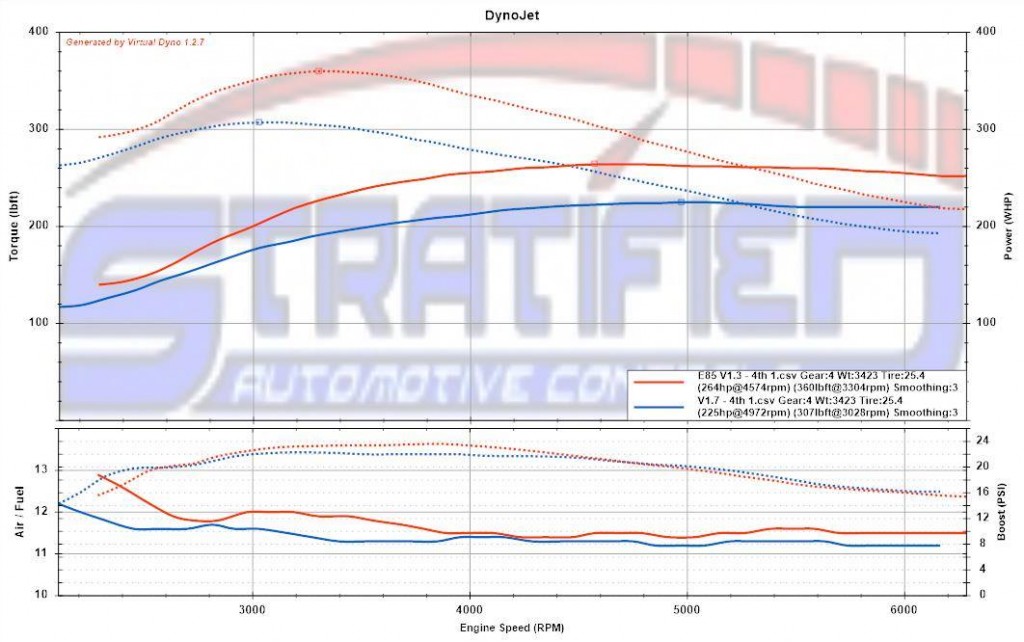

The graph below is a comparison performed in warm weather on a stock Focus ST. The blue line is a pull using straight 91 pump gas and the red is a pull with an overall E30 mixture. Although the gains in the graph below are more extreme than what we normally see due to the high temperatures and poor 91 octane fuel, they do show the increased potential of E85.

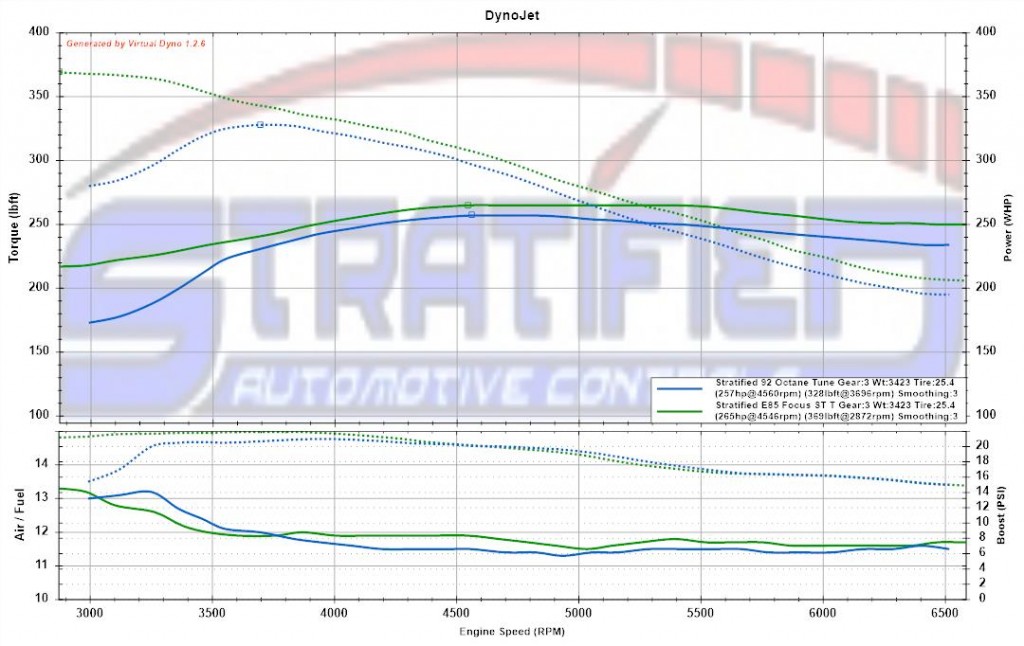

Here is another comparison; this time performed on our shop Focus ST while it was bone stock aside from a tune. The difference here (ignore the big torque peak at the beginning) is that the base fuel was of high quality and the pulls were performed in cooler weather (both things are advantageous to the straight gas tune).

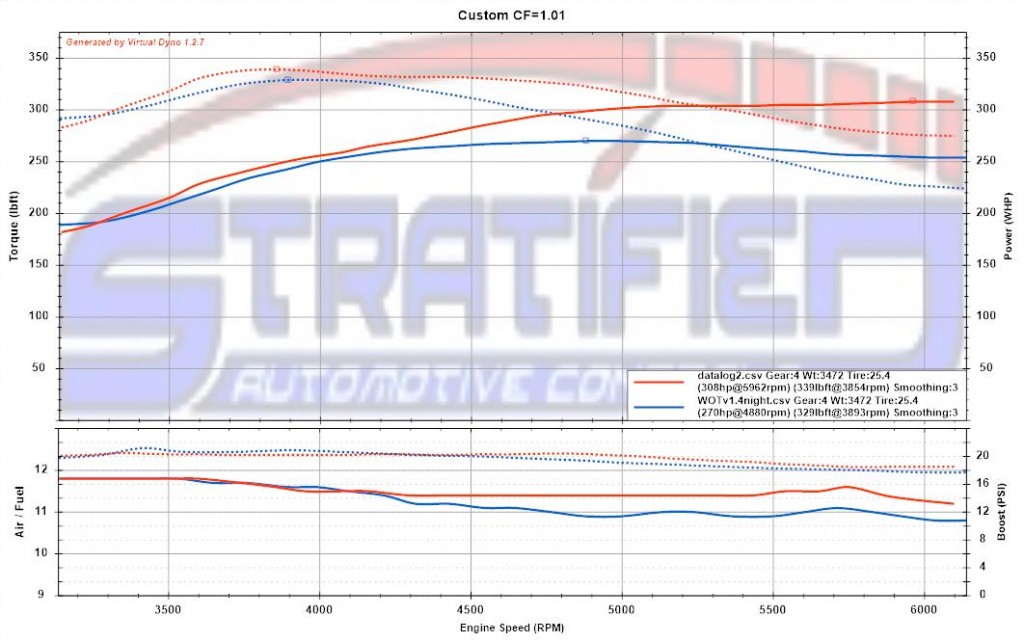

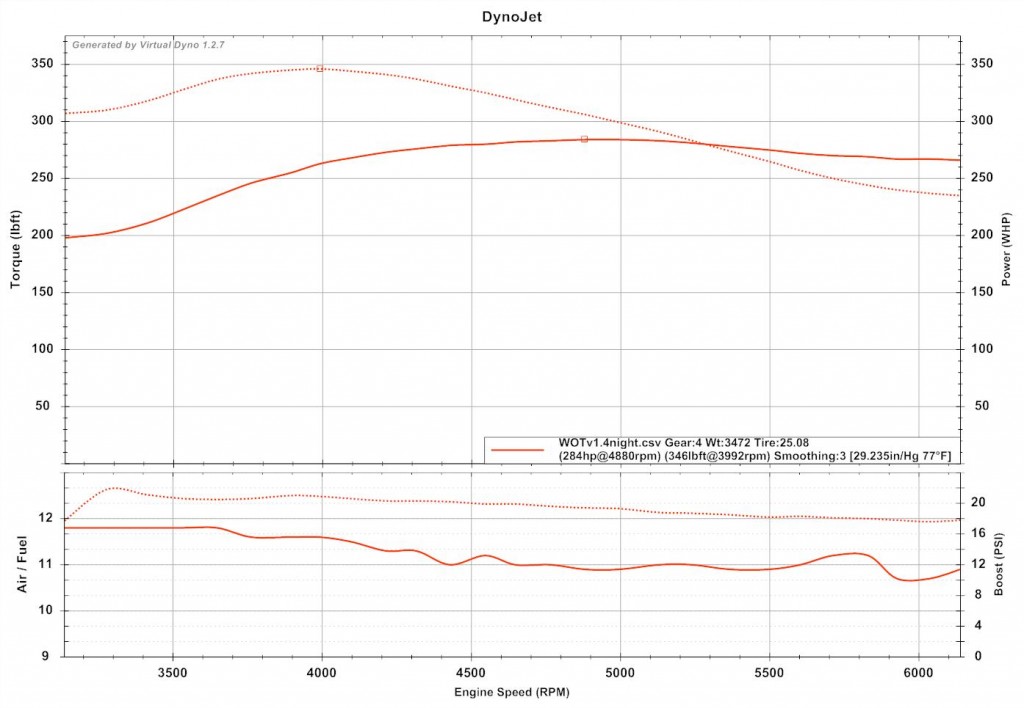

Finally, here is a comparison on a Mazdaspeed3 vehicle. Again we are comparing 91 octane to an E30 mixture. The results here are quite typical of E85 blends on a strong running Mazdaspeed3.

So how do I get tuned for an E85 blend?

Compared to gasoline, ethanol has a richer oxygen content, different specific gravity, and other subtleties which do not work well with tunes which are based on gasoline fuels. Ethanol’s increased oxygen content requires a much richer stoichiometric air fuel ratio than gasoline. What this means is that you must put in more ethanol (by volume) per unit mass of air in order to reach a stoichiometric mixture (lambda = 1). In most instances (given an OEM or similar sized turbo) this increased flow is supported by the OEM fuel system (the MazdaSpeed does need upgraded HPFP internals). In big turbo cars where power levels are reaching the 400 WHP / 400 WTQ range fueling will become an issue in both the Mazdaspeed and Focus ST motors. When working near these power levels on bigger turbos, the E85 mixture has to be done carefully such that there is enough fueling headroom left to maximize power on the OEM fuel system. Remember that achieving the most performance requires the correct mix of boost, timing, and fueling. Once you have surpassed the capabilities of the OEM direct injection system, there are aftermarket options to increase fueling such as methanol injections systems, additional port injectors (5th / 6th port fuel injection) and hopefully larger DI fuel injectors in the future. Feel free to discuss these build options with us if you’re preparing for a big power build and tune.

Whether you drive a Mazda or Ford, we offer tunes that support ethanol blends for both cars. If you own a Ford, you can go for either a full custom tune or Stratified E85 Flash Tune for your ethanol tuning needs. For Mazdaspeed DISI motors we also offer both full custom tunes as well as Stratified E85 Flash Tunes which accommodate ethanol blended fuels. Regardless of the vehicle you drive the differences between gasoline and E85 make it necessary to get a tune designated for E85 blends. A lot of our customers opt to have maps for both gasoline pump fuel as well as E85 blends and switch/re-flash between these depending on the fuel they have in the tank.

We hope this clarifies a little bit more how E85 is used in these vehicles and its benefits. If you have further questions feel free to Contact Us!

The Stratified Team