A downpipe on any turbocharged engine, if well designed, can have a positive effect on performance. If it is a better flowing unit (less restrictive) than what it replaces it will increase the pressure differential across the turbine and reduce the pumping losses of the motor. This means that the turbo will spool faster, possibly hold more boost, and the motor should also move more air per stroke. In theory this sound great but numbers are even better.

We’ve had a customer who is very consistent with his logging meaning the data logs are taken at similar ambient temperatures and the same altitude. He was able to provide several back to back logs showing the difference between a stock downpipe and a stock downpipe with a gutted catalytic converter.

As a general rule of thumb, a catalytic converter should always be used (a high flow one is fine) but this comparison shows the ballpark difference we can expect from adding a downpipe (or gutting the stock one) on a stock turbo (k04) vehicle.

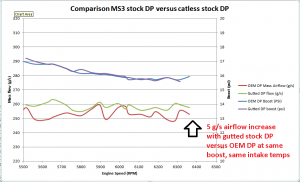

The results are below. In a nutshell, the turbo will spool faster but more importantly the engine flowed on average 5 g/s more mass air past 5500 RPM. This is worth about 5-7 horsepower at the wheels all else being equal and the gains are coming from a reduction in pumping losses alone – not an increase in boost.

Is this worth it for you?? Well that depends on your perspective. On the same vehicle, the air filter can be worth about the same in terms of power, and a 3″ intake to the turbo is worth TWICE this. That being said, the improved spool and throttle response (as well as sound) from installing a downpipe are much harder to measure and these can make for a more pleasant driving experience.

Happy Tuning!