This is a question we receive almost weekly and we want to clarify the differences as well as the pros and cons to each methodology. To explain these two tuning techniques we will have to first fully understand load and boost and then analyse the pros/cons of the two techniques.

LOAD: Load can be thought of as the amount of air entering your engine at a certain engine speed. Load is an approximation of your motor’s torque output calculated using the the amount of airflow entering the motor, engine RPM, and a scaling constant. The amount of airflow entering the motor (measured in grams/second or pounds/minute) is measured either directly using a Mass Airflow Sensor (MAF) or calculated using a Manifold Absolute Pressure Sensor (MAP).

By looking at load we have a much more realistic idea of how much torque the engine is producing regardless of turbocharger used, temperatures, and altitude. This is the most important difference between load and boost. While a car making 20psi of boost at 3000 RPM on one turbocharger will make a different amount of power to a car making 20psi at the same engine speed on a different turbocharger; a car making 2.0 load at 3000 RPM will make the same amount of power as another car making 2.0 load at the same RPM (given that the loads are calculated accurately). Because of this important distinction load based tunes are able to provide much more consistent torque across all operating conditions resulting in consistent and reliable vehicle operation. What you will see is that the ECU will vary the boost pressure to target the same load/torque depending on ambient conditions. In hotter weather the ECU will target more boost due to the lower air density and in cooler weather it will command less boost thanks to higher air density. To prevent too much boost in very hot conditions for example, our load based tunes do cap boost at a reasonable level.

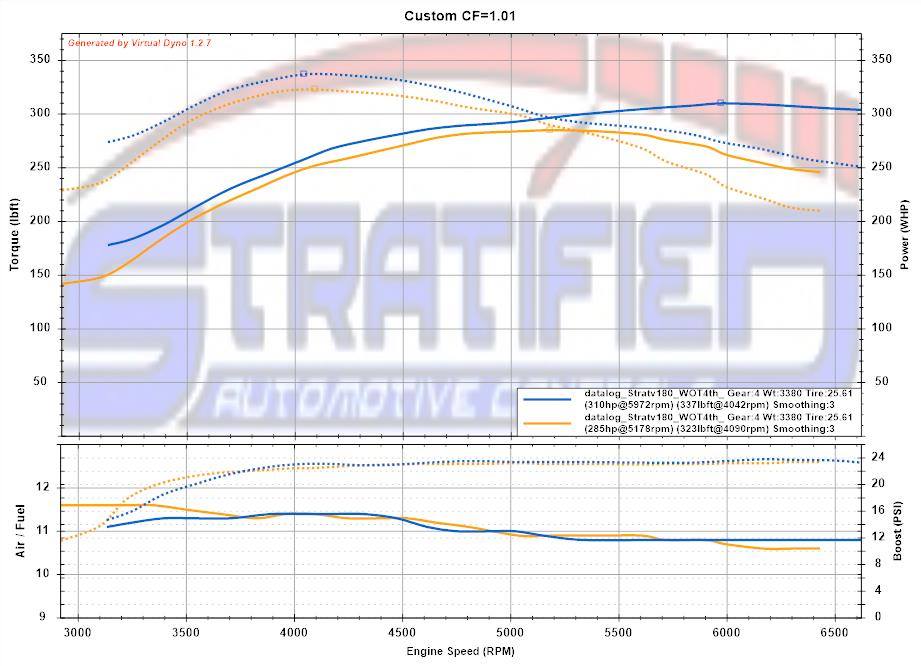

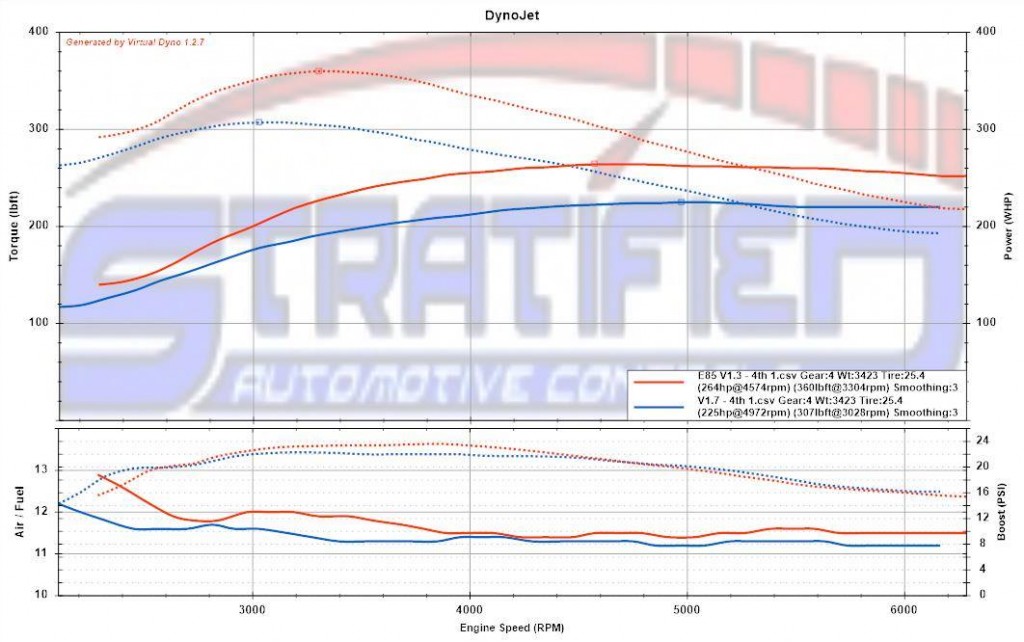

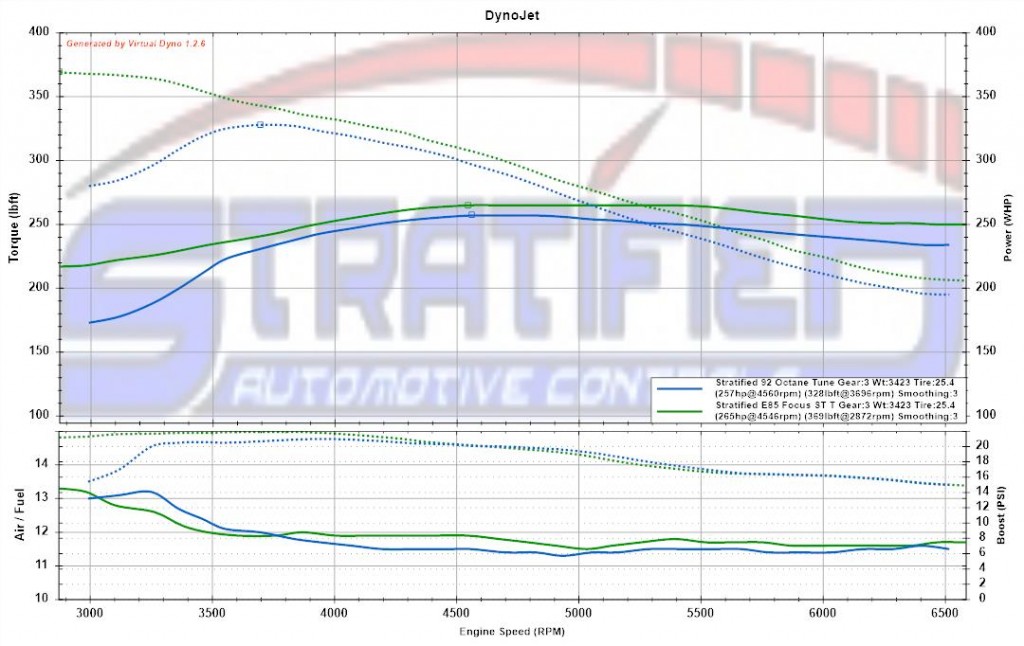

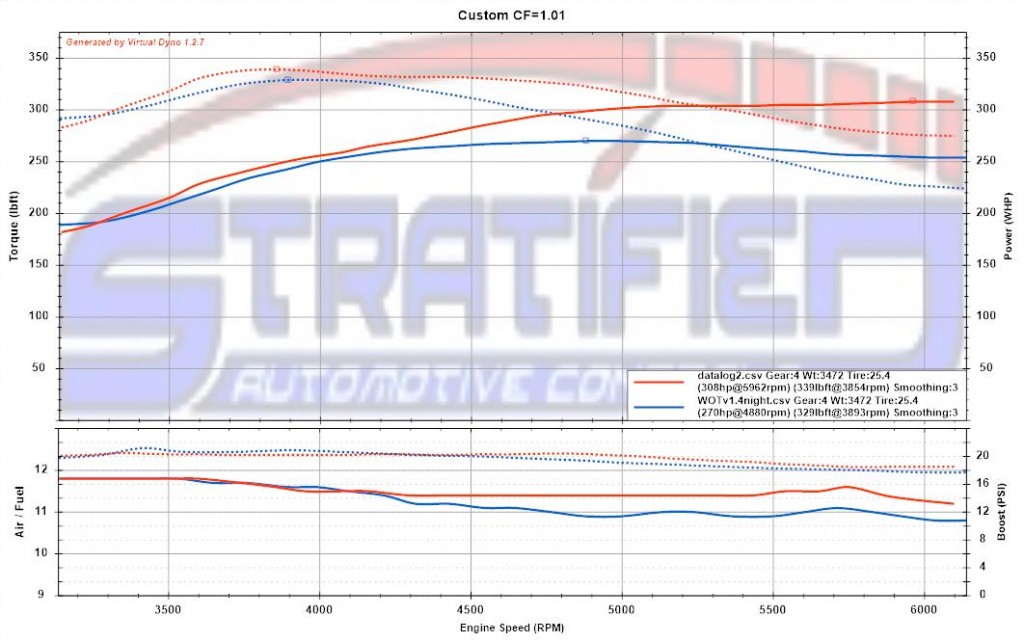

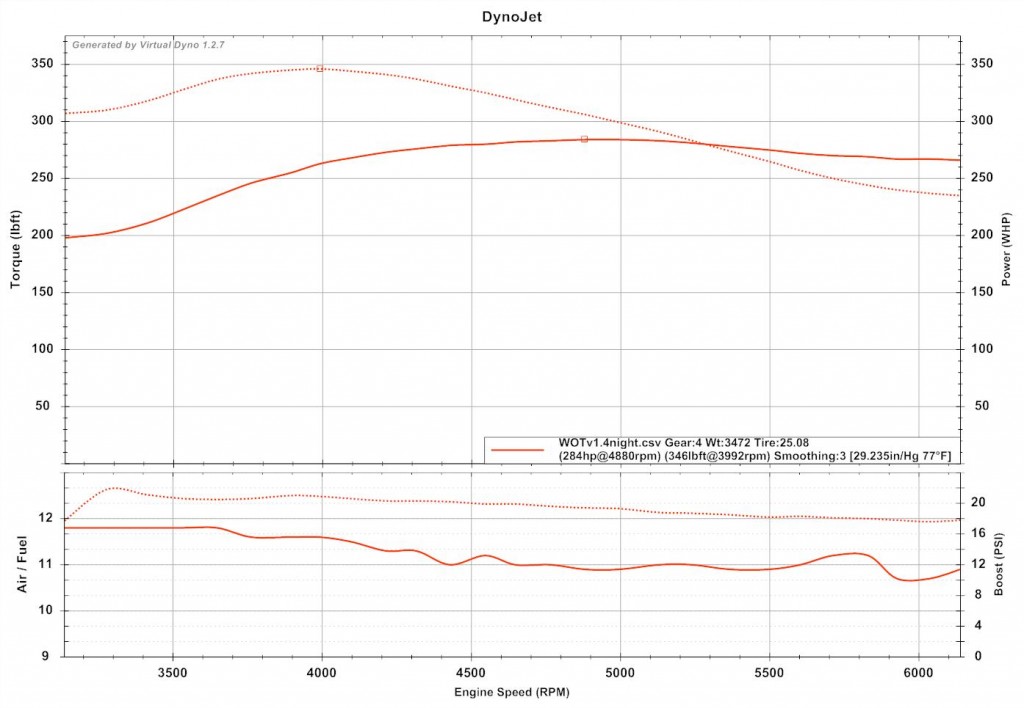

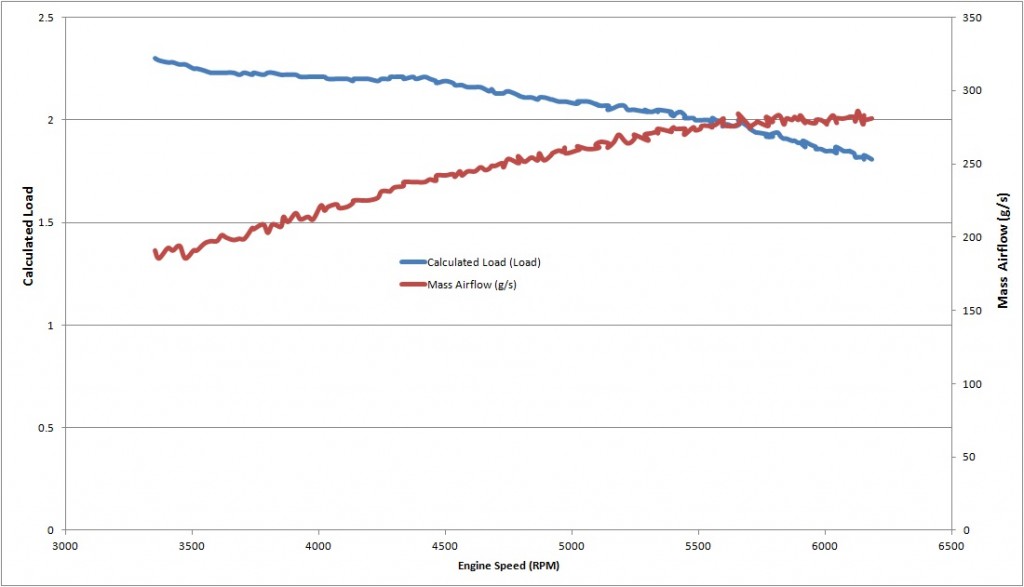

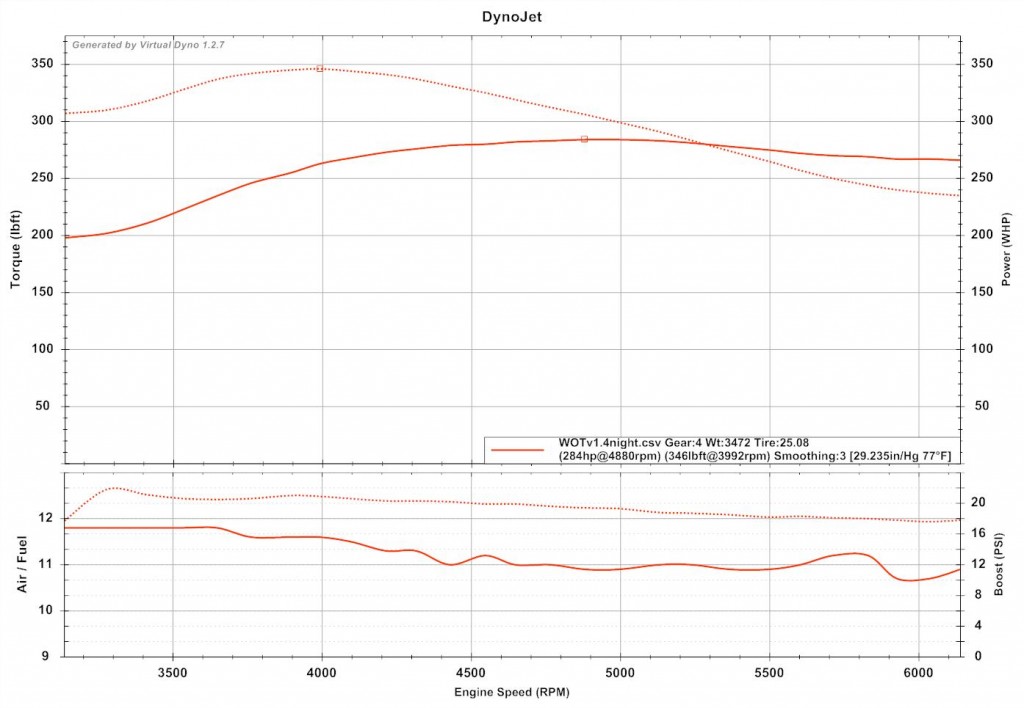

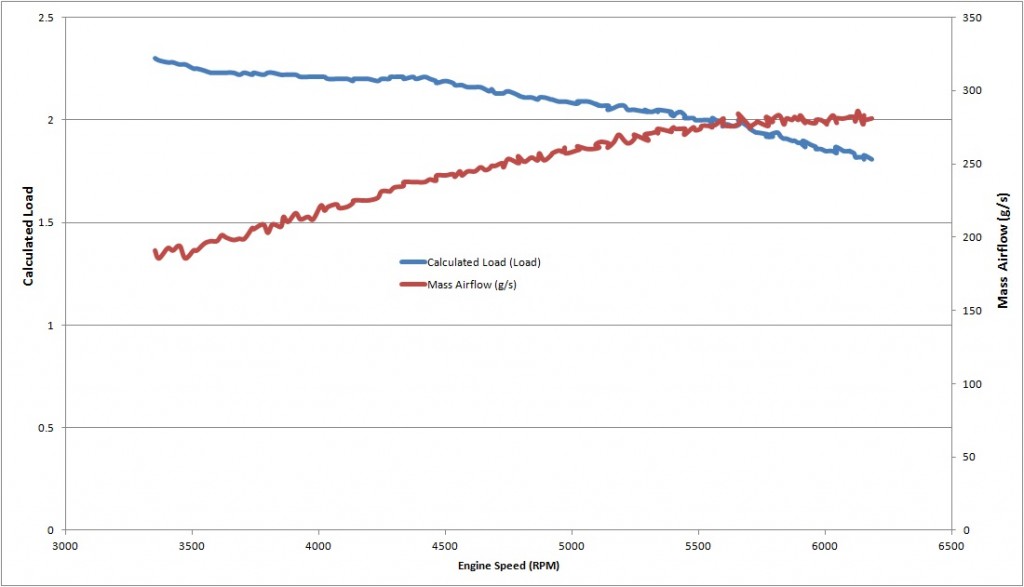

A graphical representation below shows the torque and horsepower curves of a MazdaSpeed3 vehicle. Underneath, the load and mass air flow readings from the same car are displayed. Notice how the curves look similar in shape. Indeed load correlates to torque output and mass air flow correlates to horsepower output.

Notice how the calculated load curve matches the torque curve and the measured air flow mimics horsepower.

BOOST: Your vehicle’s MAP sensor measures the absolute pressure in your intake manifold. Boost is the measure of pressure above atmospheric pressure in your intake manifold and is usually shown in Pounds per Square Inch (psi). Boost based tuning is the old school way of tuning boosted vehicles as it is an easy way of knowing what the turbo is doing. However, the mass flow rate of air as well as the amount of oxygen entering your engine at a certain boost pressure vary greatly with ambient temperature, humidity, altitude, intake, turbo used, etc. When temperatures are cooler and you are at a low altitude the ambient air has a much higher density and thus richer oxygen content than air at high altitudes and high temperatures. Because of this a boost based tune will have higher torque in the winter than it will in the summer. Our boost based tunes target boost pressures but can also put a cap on loads for engine safety.

Now that we understand the two concepts the question still remains, which is better?

Although load based tunes maintain fairly constant torque in different ambient conditions, the motor’s ability to produce torque changes. A vehicle which is targeting 2.0 load at 3,000 RPM may demand a boost pressure in the region of 20 psi during the hottest summer day. The same car will require less boost to achieve this load figure during the dead of winter since the air density is greater – let’s say it will be somewhere in the region of 15 psi (still at 3,000 RPM). Although the motor’s torque output will remain fairly constant between the two situations the end user is sometimes surprised when they see their car is suddenly making only 15 pounds of boost. In addition, since the motor has the ability to target higher load values during the winter some feel that the car’s performance is not being maximized (although now we start to worry about connecting rods).

A boost based tune which is done in the summer can have much different results than a low boost figure. Imagine a vehicle which was tuned in the summer and was able to carry 20psi of boost without knocking. This vehicle’s tune will target 20 psi no matter what the ambient conditions may be. So, as the temperatures start to drop and air density goes up, the car will be making more and more power at that 20 psi boost figure. This increases the torque output but also puts more strain on the connecting rods and fuel octane being used due to higher cylinder pressures.

OEM tunes target loads because they want to deliver consistent output year-round (the rated engine output). Because of this the control system has nice features such as load by gear which enhances traction and driveability. While we can switch to a boost targeting strategy, some of these driveaibility enhancing features can’t be used as effectively.

We, at Stratified, choose load based tunes based on their reliability, driveability and the consistent torque delivery which is virtually independent of ambient conditions in the majority of cases. However, some cars and setups are better suited for boost-targeting tunes than others and if we know the user’s goals from the get-go we can choose a strategy that suits them best. Some of these include:

– Cars using E85 or very high octane fuel where knock is not much of an issue.

– Cars with built motors that want to maximize power output all the time and are not worried about damage/breaking components.

– AWD cars that don’t need torque by gear output limitations.

– Cars/people that want to get the absolute maximum power from their setup all the time with less concern for driveability or long term reliability.

Hope this makes the distinction between load based tuning and boost based tuning a little clearer and helps you choose the right strategy for your car. Just like with everything else, choose the tuning method best suited for you and your vehicle.